Benifits Of Using Mdf For Packaging: Lower Cost Than Wood And More Rigid Than Paper Boxes

At first glance, “wooden box packaging” may sound like nothing more than a simple container — just a wooden box, how hard can it be? But for those who actually work in this field, things are far more complex. Turning a piece of raw wood into a box that not only protects but also reflects the identity of a product requires careful material selection, craftsmanship, and technical skill. Unlike plastic or paper packaging, wood carries a natural and refined quality that demands precision in both design and processing. For example, in addition to solid wood, there is another commonly used material: MDF.

01 What is MDF? Is MDF a fake wood?

MDF is a type of density fiberboard, which also includes long-fiberboard and short-fiberboard. Made from wood fibers or other plant fibers, it undergoes a process of crushing, fiber separation, drying, and application of urea-formaldehyde resin or other suitable adhesives before being made into wooden boxes. Finally, it is heat-pressed to create a man-made board. The density of MDF (Medium Density Fiberboard) is generally between 0.5 and 0.8 g/cm³, and its thickness ranges from 3 to 30 mm. This can be modified based on customer requirements, but this is relatively rare. Since solid wood can already be used to make wooden boxes, why is MDF still used? What are its specific uses and characteristics?

02 What are the advantages of MDF?

Due to its excellent performance and its role as an effective means of comprehensive and rationally utilizing wood, medium-density fiberboard (MDF) is one of the most promising products currently.

03 How to choose the density of MDF?

Density fiberboard (MDF), also known as fiberboard, is a man-made board made from wood or other plant fibers, coated with urea-formaldehyde resin or other suitable adhesives. Based on their density, they are categorized as high-density fiberboard (HDF), medium-density fiberboard (MDF), and low-density fiberboard (LDF). MDF is a popular material for furniture production abroad due to its softness, impact resistance, and ease of reprocessing. However, because national standards for high-density fiberboard (HDF) are several times lower than international standards, the quality of MDF in my country still needs to be improved. According to national standards, medium- and high-density fiberboard (MDF) refers to boards made from wood or other plant fibers, coated with urea-formaldehyde resin or other suitable adhesives, and with a density between 0.50 and 0.88.

04 How to make an MDF box?

If you’ve already decided on the box you want, take a look here:

- For high-end tea (ancient tree tea, Pu’er), use moisture-proof flocking for the interior, gold-stamping for the exterior, and laser cutting crafts.

- For high-end watches (Swiss movement), use ultra-soft flocking for the interior, laser cutting for the exterior, and a matte finish. Use a hardness test pen to ensure the surface’s compressive strength is high.

- For gold or diamond jewelry, use light-colored flocking for the interior, pure copper lettering for the exterior. Make sure the formaldehyde content is low, and use copper hardware to prevent rust.

- For limited-edition vintage wine, use slotted EVA for the interior and a laser cutting crafts.

05 How to choose MDF packaging (5 key tips)

- Smell test: For food, tea, or cigars, seal the box for 24 hours — if there’s a strong smell, avoid it.

- Don’t oversize: Bigger boxes cost more (more paint, more material). Make the box just the right size for your product.

- Invest in hardware: Use copper or stainless-steel hinges and locks. Iron fittings may rust and look cheap.

- Surface finishing: Countless options exist — laser engraving, screen printing, UV printing, metal lettering, hot stamping, embossing, water-transfer printing. Choose what fits your brand.

- Opening mechanism: From magnetic closures to vintage locks or even puzzle-like mechanisms, pick according to the product’s style.

These are all personal choices based on your product. Choosing a wooden box isn’t that complicated. First, think clearly about what you want to put in it, your budget, and your product’s value. Don’t blindly choose expensive options; the best packaging is one that truly matches your product’s value.

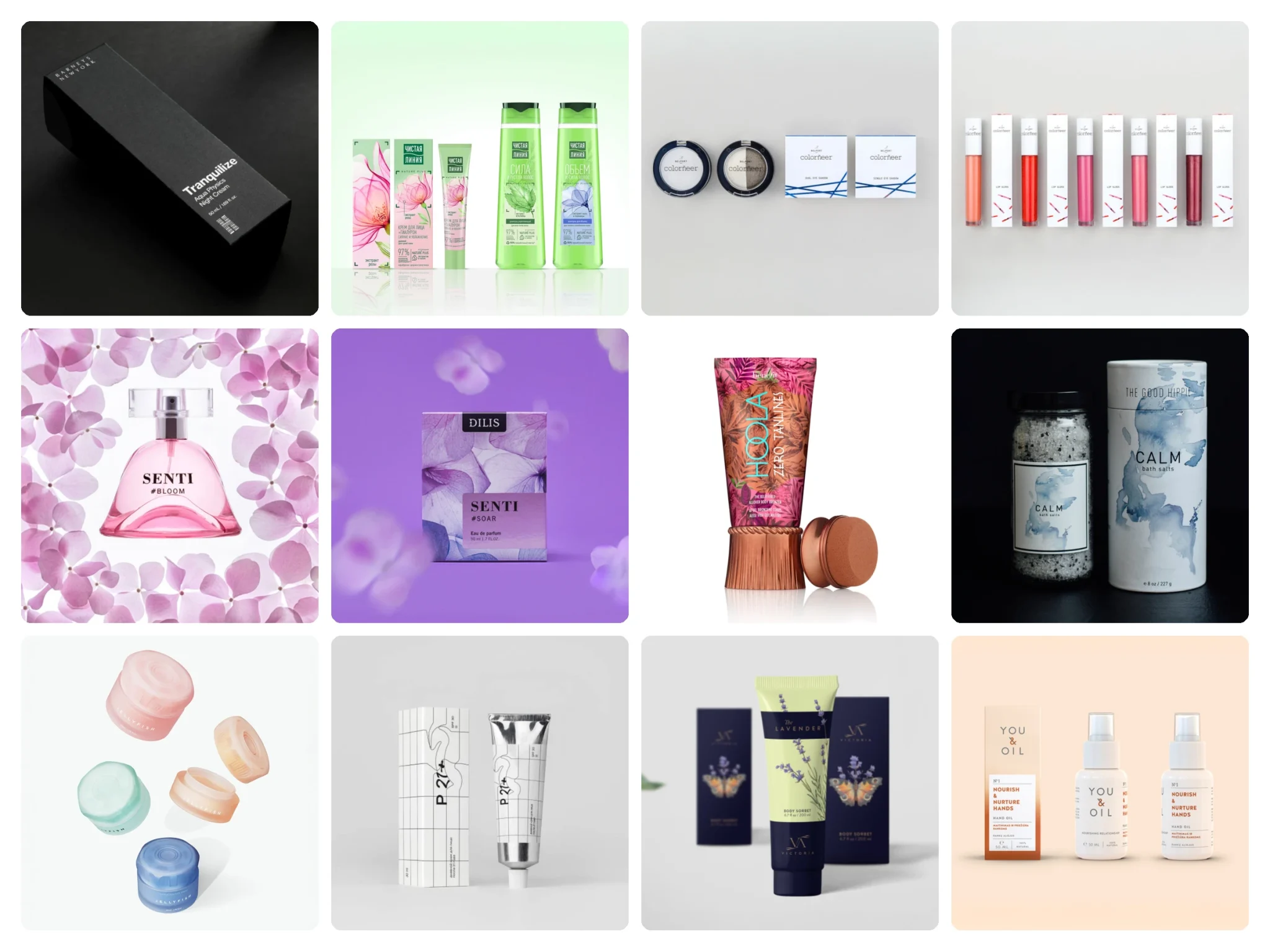

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

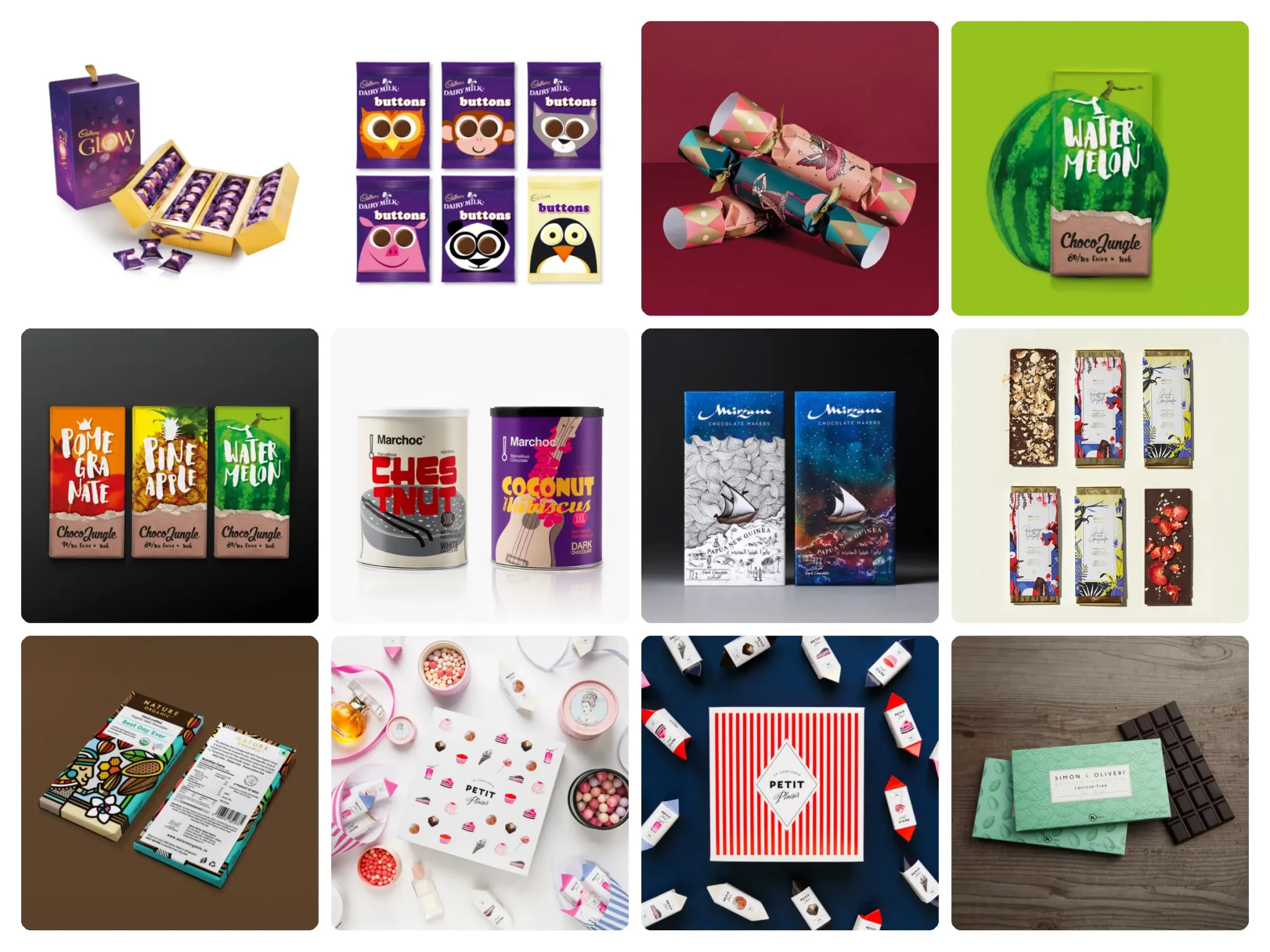

30 Honey Packaging Designs That Capture Nature’s Sweetness