Eco-friendly Packaging Box Structure Design Ideas

As companies accelerate their efforts to achieve the Sustainable Development Goals (SDGs), an increasing number of companies are reviewing and improving packages. Not only the replacement or improvement of materials, but also the structural design of the packaging box can achieve a more environmentally friendly effect. In this guide, we will break down some Eco-friendly Packaging Box Structure Design Ideas.

How To Make Your Packaging More Environmentally Friendly in Structure?

How To Design Your Packaging Box Structure in More Environmentally Friendly Manners?

We have frequently seen cases where environmental impact is reduced by switching materials, such as changing plastic packaging to paper = “cardboard” or changing the raw materials of packages to recycled raw materials and plant-derived raw materials, in recent news, press releases of each company, advertisements, etc.

Until now, Luxury-Paper-Box.Com has continued research and development not only on materials but also on “structural design of packaging box” that have a less environmental impact. Therefore, this time, we will introduce an environmentally friendly packing box structure design with three specific examples.

Considering the Eco-friendly in Packaging Box Structural Design

Among the total packages sold by Luxury Paper Box, the proportion of the total number of packaging boxes sold by Luxury Paper Box is increasing year by year. In order to properly protect the products inside, we mainly process cardboard and cardboard sheets in packages that require a particularly precise structural design.

Paper and corrugated cardboard are materials with a lower environmental impact than plastics because of their high recycling rate and material made of circulating resources.

When you think about the energy required during manufacturing processes and transportation, it does not mean that you can use as much as you want just because the environmental impact is low. It is important to use only the necessary amount according to the application and purpose, that is, “eliminate waste”. In the structural design of a package, care must be taken to ensure that the package plays its original role while cutting off waste as much as possible.

The role of packaging is not only to protect products but there are many other roles. Specific examples include appealing to the concept and information of the contents through design, increasing consumers’ desire to purchase, and making it easier to display on product shelves by devising shapes.

Proposing a package box with a proper structural design by eliminating unnecessary parts or incorporating completely different ideas while satisfying the conditions necessary to properly fulfill the role required for each package.

Eco-friendly Packaging Box Structure Design Ideas

Here are three specific examples of environmentally friendly package structural design.

- Insert Boxes – Makes products stand out while reducing the amount of paper used

Features:

- The body box is shallower than usual, and the amount of paper used can be reduced.

- There is a lot of areas where you can see the product, it looks gorgeous, and it looks good in photos.

- Easy to take out the contents

Suitable for putting inside:

- Products that are required to look good and products that are posted on catalogs and websites (Tea, cosmetics, perfume packaging for gifts)

The first thing we would like to introduce is the “Insert box”. As the name suggests, a stopper box is a package with a “insert” inside the lid. Unlike general lid / body separate type boxes, the feature is that the body box is considerably shallower than the depth of the lid. Normally, if the lid is deep and the body box is shallow, the lid will fall too much = the body box will get inside the lid, but the “insert” inside the lid prevents it.

It can be said that it is an “environmental-friendly package structure design” in that the amount of paper used can be reduced as the body box becomes shallower than usual.

And the benefits of insert boxes aren’t just about being environmentally friendly. When you put the product in the body box, the area where the product can be seen increases, so the appearance becomes gorgeous and you can produce a sense of volume. Consumers also benefit from the fact that they can easily retrieve products.

When taking a photo of a product, the product inside looks bright, so it is ideal as a package for products posted in catalogs and websites, and it is a format that is often adopted for using Japanese tea and tea cans for gifts.

- Lean Cross Pack – Excellent versatility

Features:

- Flexible and versatile, reducing the types of packaging materials to prepare

- Flexible and versatile, reducing the types of packaging materials to prepare

- It is possible to remove paper without waste, and there are few parts to be discarded during manufacturing.

- Can be manufactured at low cost

Suitable for putting inside:

- Items that have a certain shape, but the size is slightly different depending on the product (CDs, books, etc.)

Next, we will introduce Cross Pack. As the name implies, a cross pack is a package that is assembled by crossing. Here is the state before wrapping the product. At first glance, it looks like just one sheet. Wrap the product by lifting the notch in the sheet and crossing the part with the ruled lines. The feature is that it can be used for various products by folding it according to the height of the product when wrapping it.

Since crosspacks do not form as boxes by themselves, they are often manufactured using relatively strong materials such as one-stage (cardboard with only one side naruded) sheets and cardboard. Since it can be used as a package for various products and is highly versatile, it is possible to reduce the type of packaging material because it is not necessary to prepare a package of the size according to each product inside.

In addition, since the state = expansion diagram before wrapping the product becomes rectangular, efficient and lean paper removal is possible. This not only reduces the amount of paper you throw away, but also reduces the cost per package.

The features of crosspacks are most effective when wrapping things that have a little difference in size depending on the product, while the shape is determined to some extent. Therefore, it is recommended to use it for applications such as CDs and books.

- Thin but strong FS cake box – Strengthen the material with the power of design

Features:

- Reinforcing ribs are included in the back part, so it is possible to give strength even with thin paper

Suitable for putting inside:

- Cake, Dessert, Other Food Products (Especially when you want to reduce the amount of resources used or when you want to make the thickness of the paper used as thin as possible)

Lastly, we will introduce “FS Cake Box”. In the past, two specific examples have reduced the amount of paper used by devising the “shape” of the package, but fs cake boxes are characterized by reducing the amount of paper used by reducing the thickness of the paper itself used.

Normally, it is necessary to select the appropriate paper thickness depending on the application and the weight of the product to be put in, but even when using paper thinner than the appropriate thickness, it is possible to compensate for the strength by devising the design.

Fs cake boxes are an example. The back part of this package is the weakest part because the overlap of the paper is only the part where it is glued. Therefore, by putting reinforcing ribs (irregularities shaped like ribs) in this back part, the strength can be increased.

In order to protect the products inside, it is important to use paper of appropriate thickness, but “I want to reduce the resources used as much as possible to reduce the environmental load” “Paper used to reduce inventory space” Is a suitable package when you want to make it as thin as possible.

Proper Structure Design for Eco-Friendly Packaging Boxes

We have introduced three specific examples of environmentally friendly package structure design. There are various material variations depending on the product to be put in, the purpose of use, the purpose of use, and the emphasis, but there are also many variations in the structural design as well.

Luxury Paper Box has a large number of staff who specialize in the structural design of packaging boxes, and in order to meet the needs of our customers, we are ingeniously devising while facing the packages every day.

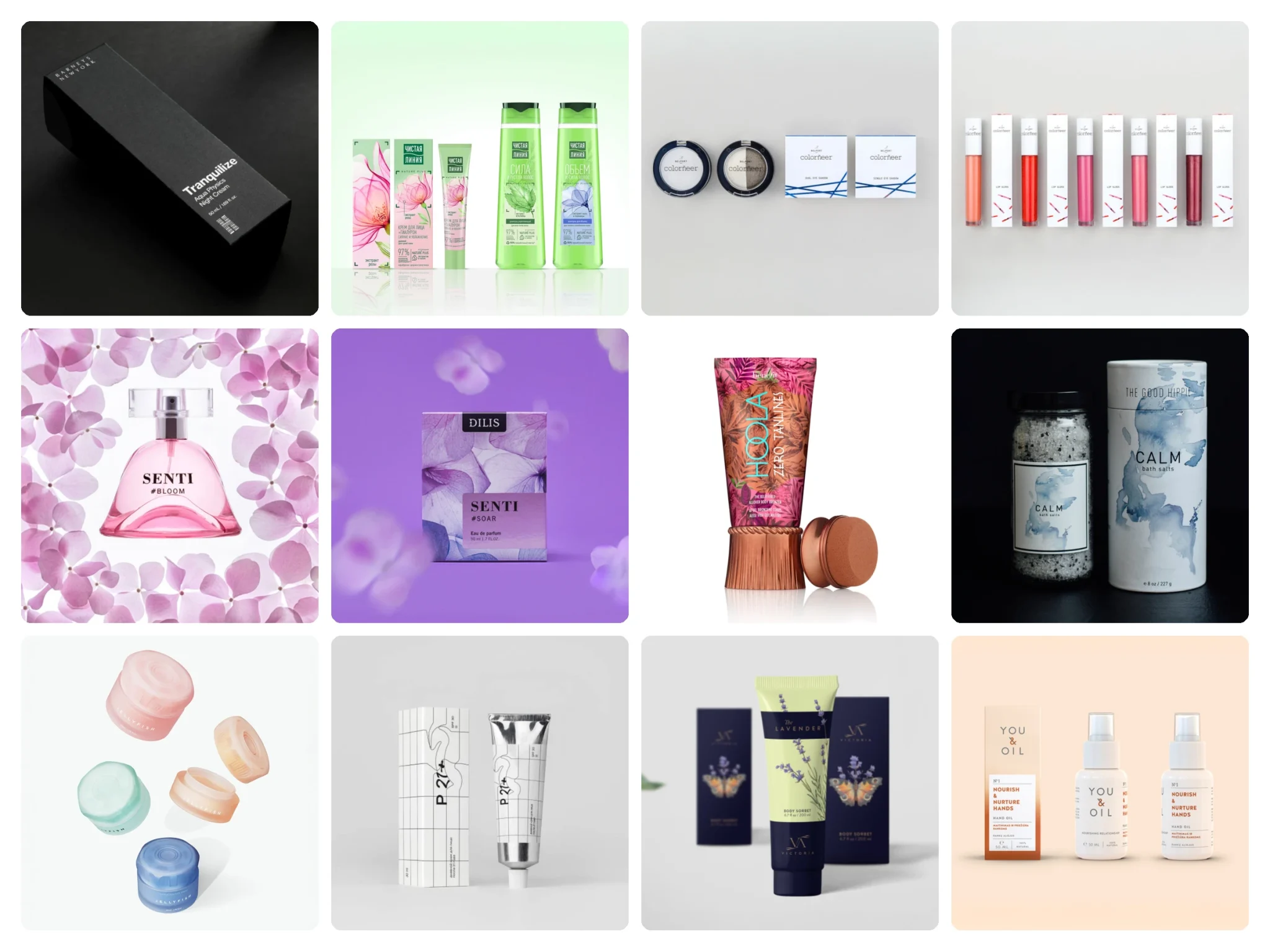

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

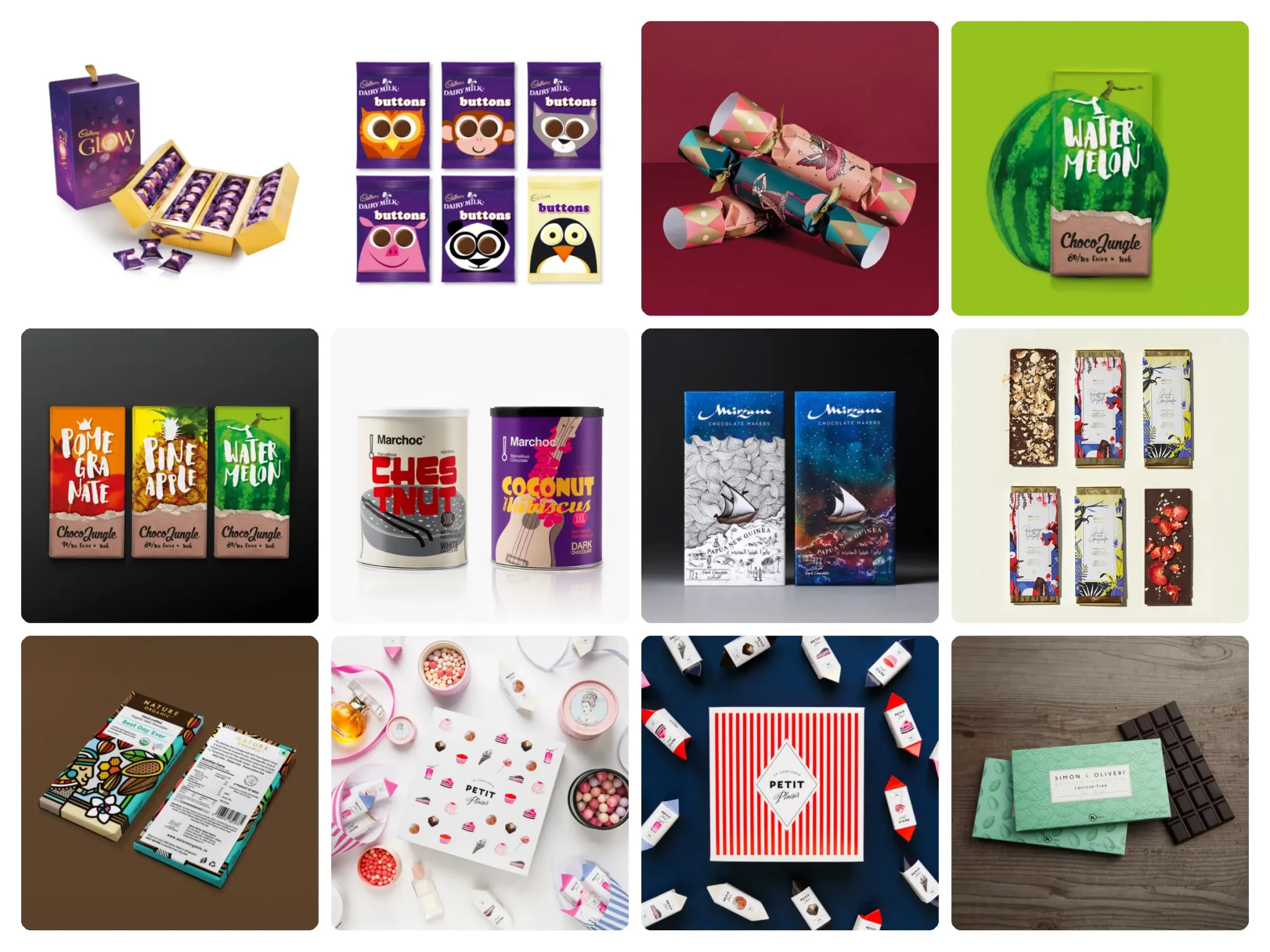

30 Honey Packaging Designs That Capture Nature’s Sweetness