Gang Run Printing: the Secrets & Advantages in Short Printing

What is Gang Run Printing?

Gang run printing is a method where products from different customers are printed together on the same paper stock, using the same color number and run length on a single large printing plate. This maximizes the printing area on a larger press, allowing multiple small-format prints to be produced at the same time. By doing this, it reduces printing costs, spreads out expenses for platemaking, and lowers production costs overall. It’s ideal for standardized products like business cards, flyers, and cardboard packaging.

For traditional printing, the larger the print run, the lower the cost per page. This makes gang printing an effective way to cut costs compared to specialized printing. Gang run printing also offers lower prices and faster delivery times, which works well with the needs of the internet economy. This can attract more customers, especially those who don’t have specific, complex printing requirements. Gang printing is great for businesses that need routine, straightforward products.

Characteristics of Gang Run Printing

Gang printing is suitable for products that share the following characteristics:

- Small size

- Low quantities

- Similar material requirements

- A large number of separate files

These features allow multiple small jobs to be combined into one print run. As a result, products like business cards, paper bag, det cut box, especially short run labels are commonly printed using this method. From a cost perspective, traditional special printing tends to have higher starting costs, which is why short run digital printing works as an alternative. Gang printing organizes and manages a large number of small orders based on their similarities, then prints them all together, cutting them out and selling them separately.

Advantages and Disadvantages of Gung run Printing

Advantages

- Lower unit price: Small batches can save 30%-50% in costs.

- Faster delivery: Shorter production times.

- Environmental benefits: More efficient use of resources through centralized production.

Disadvantages

- Limited flexibility: Not ideal for large, complex projects.

- Initial setup cost: Setup costs may be higher for very small quantities.

- Material constraints: Certain materials may be less available in small quantities.

Why Are More People Using Shortrun Printing Like Gang Run Printing?

The main reason is cost reduction. Gang printing helps minimize costs in three key areas: investment, production, and labor. By cutting costs in these areas, printing companies can create a more efficient combined printing model.

Another advantage is speed. High efficiency allows more jobs to be completed in less time, which requires automated equipment and digital solutions.

Additionally, software and platforms that support gang run printing are improving. These include tools for smart ordering, billing, color management, and automated platemaking, along with websites and payment systems that simplify the process.

Short run printing offers two main benefits:

- It increases efficiency, enables faster delivery (sometimes within 24 hours), and focuses on customer service, allowing printing companies to shift from being production-focused to service-focused.

- It provides standardized products. E-commerce printing companies typically offer standardized items, where customers only need to specify content, document size, and paper type.

For the future of combined printing, companies must focus on four key areas:

- Improving internet operations

- Reworking front-end design

- Standardizing post-press processes

- Offering more product variety and differentiation

What’s the Future of Gang Run Printing?

A financial report from a leading gang printing company shows that its traditional short run printing business saw a 28% drop in profit margin in 2024. Meanwhile, revenue from customized printing increased by 45%. This isn’t unique—gang run printing is facing three major challenges:

1.Higher quality demands: Companies want better quality and faster delivery, but the “make-to-order” model of combined printing often leads to problems like color inconsistency and unreliable production schedules.

2.The rise of digital printing: On-demand printing technology has improved, and small orders now cost about the same as gang printing. Digital printing can also handle variable data, allowing for personalized printing on each sheet.

3.The end of the traffic dividend: Rising costs to acquire customers online make the “small profits, quick turnover” model unsustainable for short printing companies.

Industry Implications: The “low-price competition” in gang run printing has reached its limit. The new focus is on “quality and fast response,” which is the next competitive advantage in the printing industry.

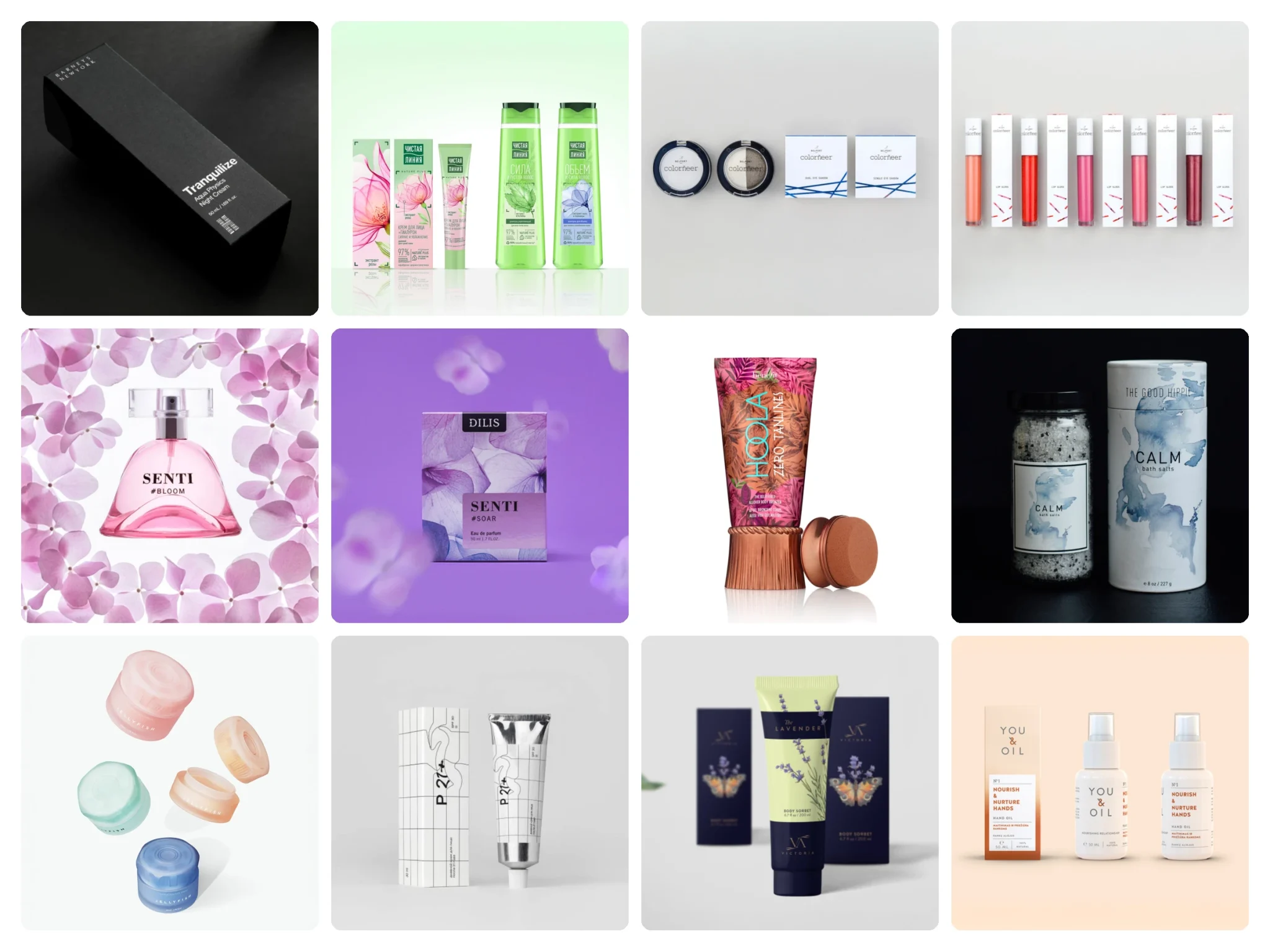

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

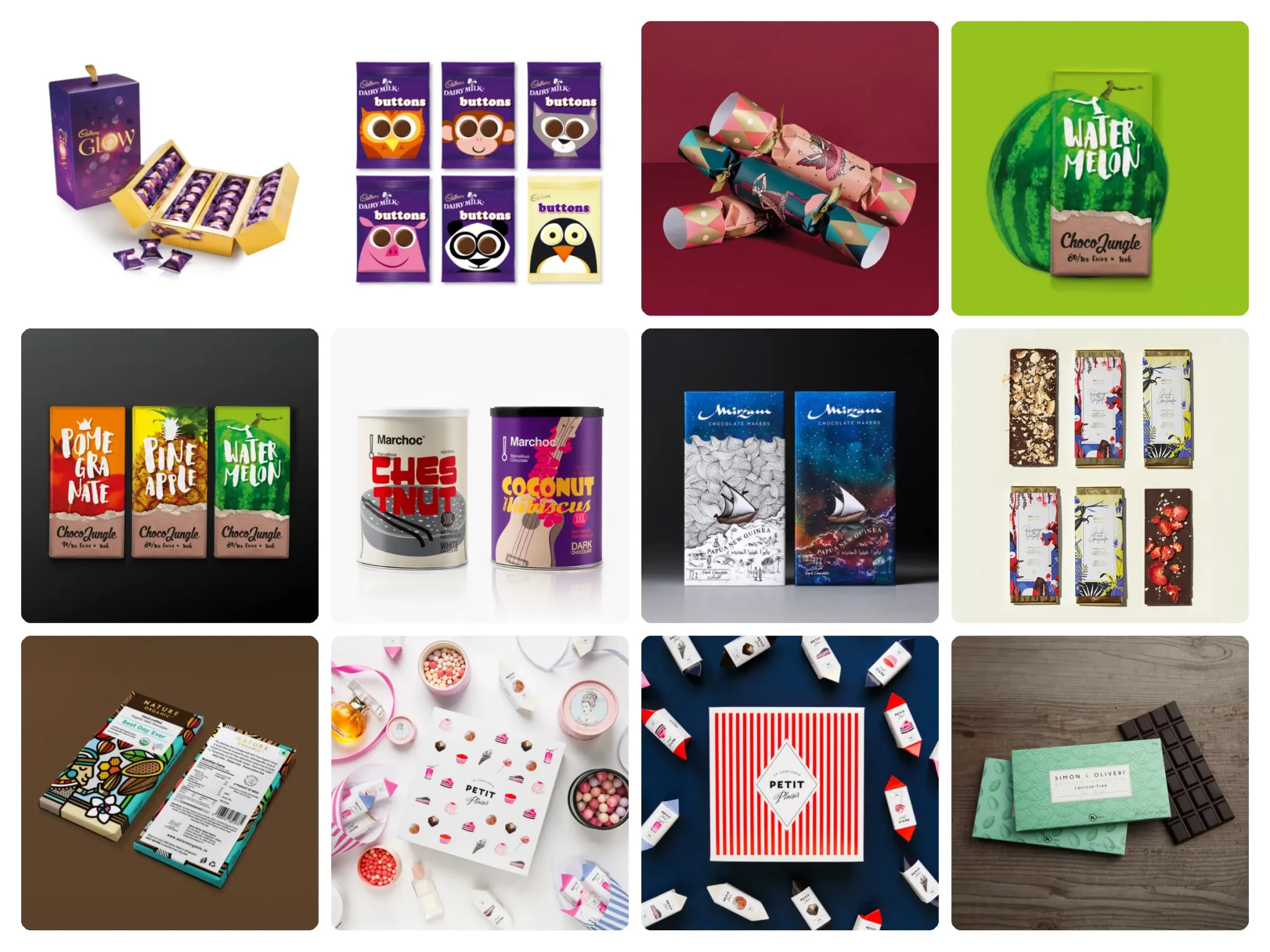

30 Honey Packaging Designs That Capture Nature’s Sweetness