Guide to Reduce Shipping Costs With the Right Ecommerce Shipping Box Choice

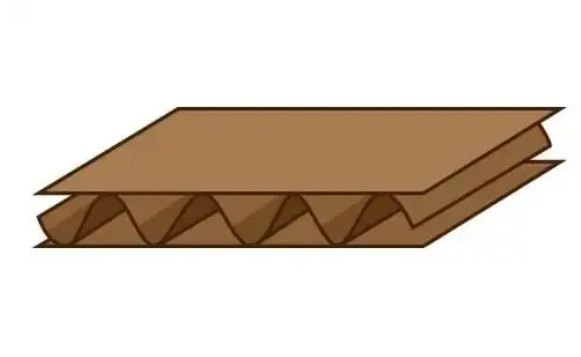

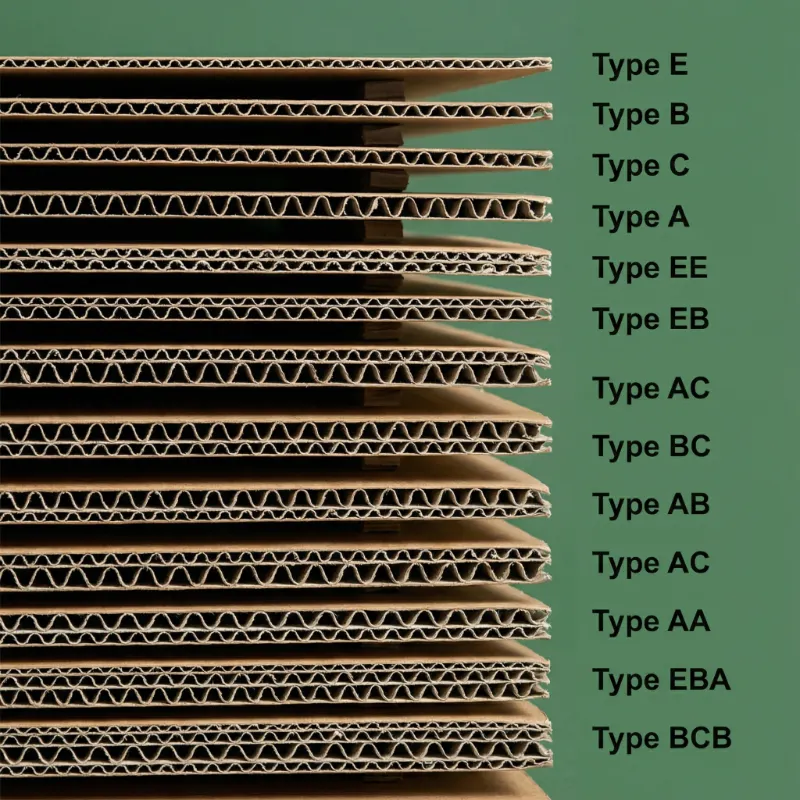

In the early 20th century, people realized that corrugated cardboard with different flute sizes—such as A, B, and C flutes—behaves differently. Some types are stronger, some provide better cushioning, and others have a smoother surface. By choosing the right flute for each purpose, manufacturers later developed double-wall and triple-wall corrugated boards, which can support much heavier loads.

What You Should Know About Corrugated Boxes?

1. What Types Of Corrugated Board Sheets Are Commonly Used In E-Commerce?

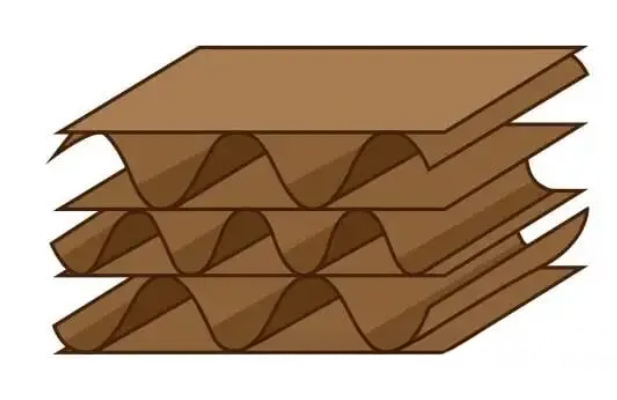

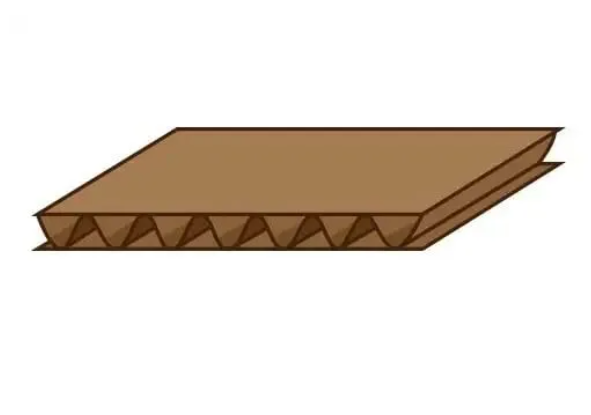

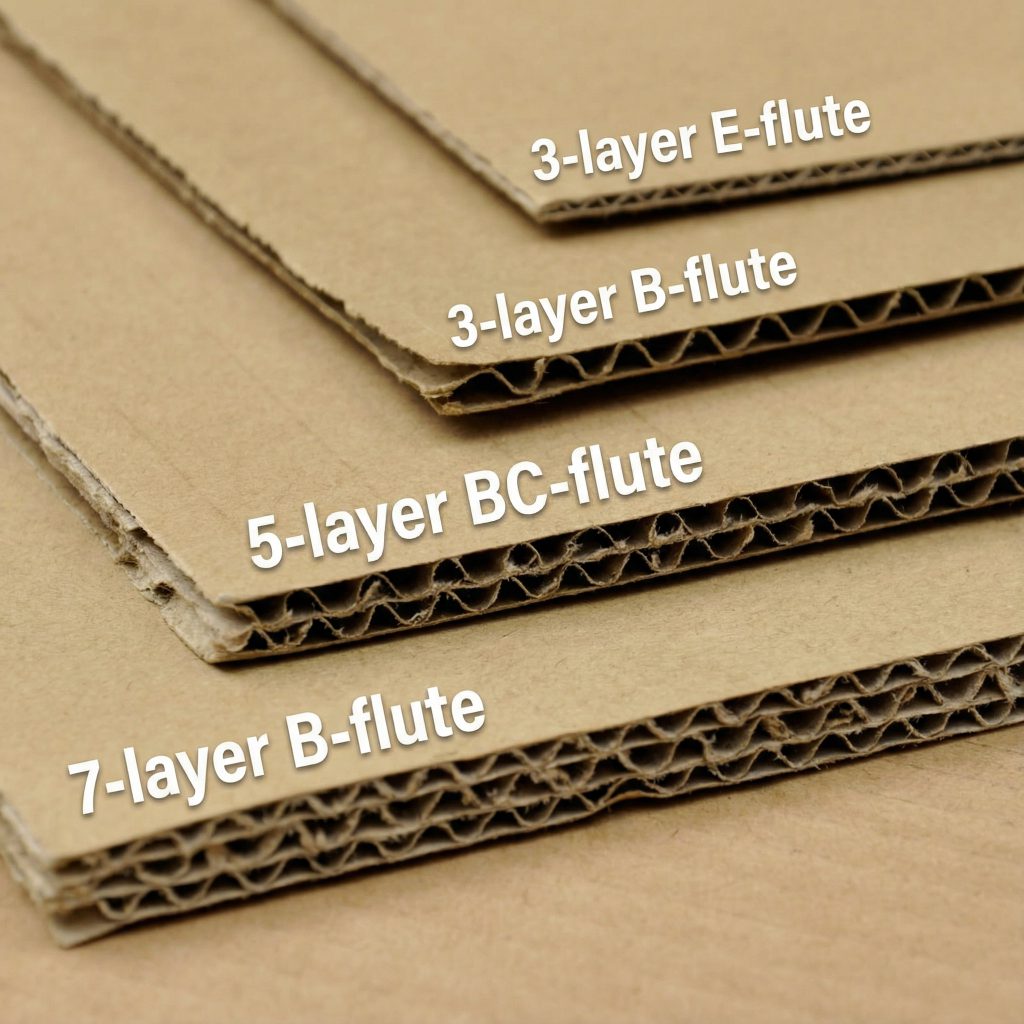

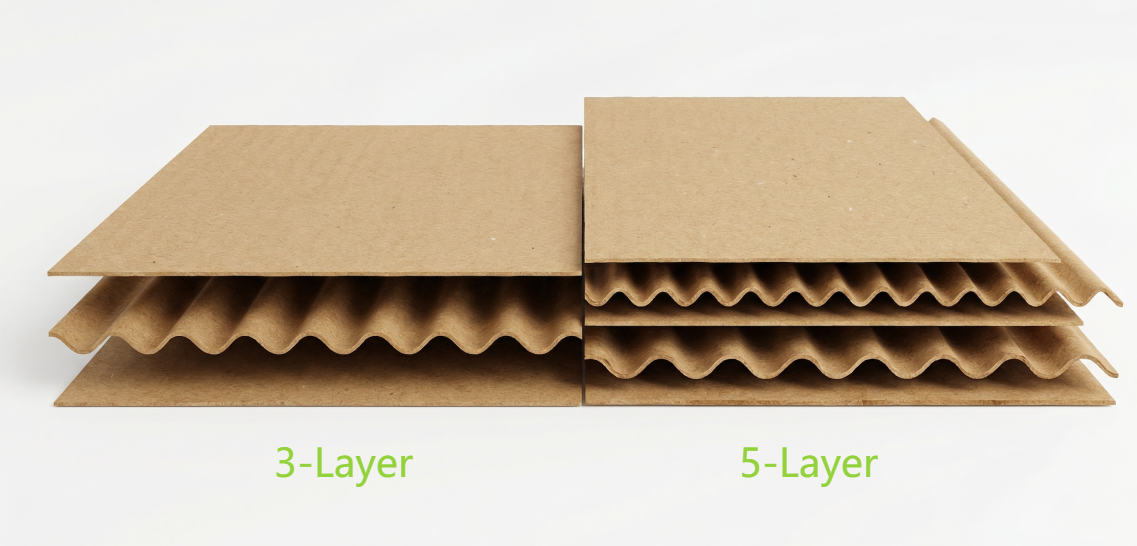

Three-layer (single-wall corrugated):

The most common type of shipping carton, suitable for ordinary products under 5 kg, such as clothing, snacks, and small household appliances.

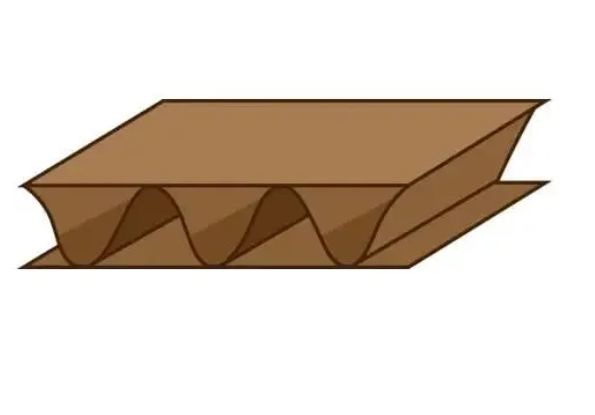

Five-layer (double-wall corrugated):

Provides higher compression strength. Suitable for 5–20 kg heavy or fragile items, such as small furniture, cosmetic gift sets, and precision instruments.

Seven-layer:

Designed for extra-heavy-duty use, such as moving and industrial applications, and generally not needed for everyday shipping.

2.What Types of Corrugated Flute Types Are There?

Corrugated flutes are an essential part of packaging materials. There are five main types of corrugated flutes: A, B, C, E, and F. These flutes vary in thickness, ranging from approximately 0.8 mm to 5 mm. The naming of corrugated flutes follows the order in which they were invented: A represents the earliest developed flute, while F represents the most recently developed one.

3.How to Quickly Choose the Right Shipping Box Load Capacity?

B Flute

Description:

With a relatively higher flute height (about 2.5–3.0 mm), B-flute offers excellent vertical compression strength. It is extremely load-resistant and well suited for applications that require strong structural support.

Summary:

Shipping cartons with high load-bearing requirements, structural components of large display stands, and logistics packaging. load-bearing capacity, compression resistance, transport protection, or structural support — B-flute is the right choice.

Typical applications:

Heavy-duty cartons, appliance packaging, logistics boxes, and the load-bearing bases and frames of display stands.

E Flute

Description:

With a lower flute height (about 1.1–1.4 mm), E-flute is stiffer and offers high flat crush strength. It is ideal for inner partitions and product inserts that protect surfaces from scratches, but it is not suitable for withstanding high vertical loads.

Summary:

If you need refined printing quality, a premium feel, or packaging for high-end gift boxes and inner supports — E-flute is the best choice.

Typical applications:

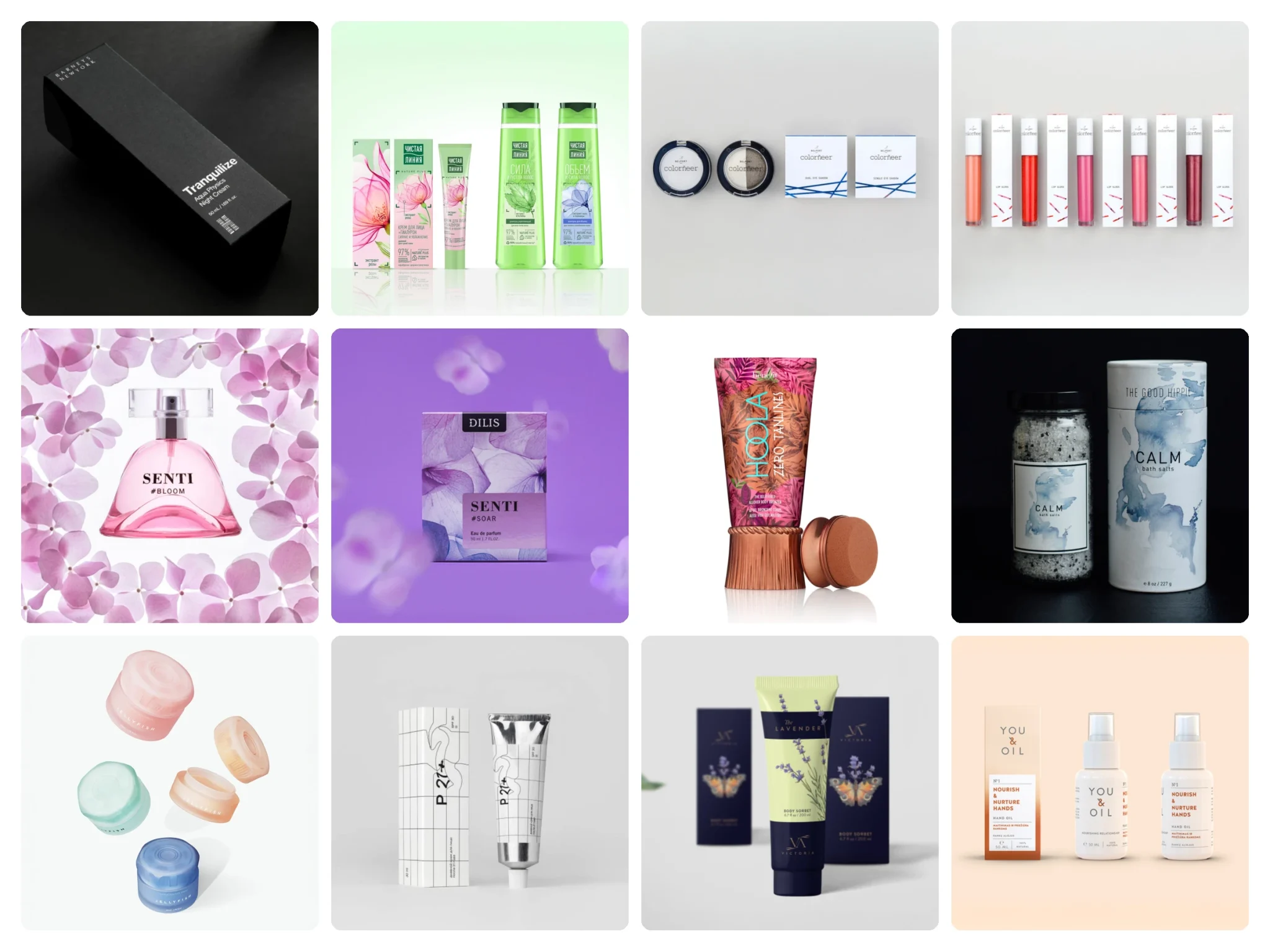

Cosmetic display stands, perfume boxes, mobile phone boxes, affordable luxury gift packaging, and small food packaging.

4. What Are the Different Types of Corrugated Flute Profiles Used for E-commerce Business?

| Flute Type | Flute Height (mm) | Flute Thickness (mm) | Flute Count (per 30cm) | Features & Application Scenarios |

|---|---|---|---|---|

| E Flute | 1.1 – 1.4 | 3.0 – 3.3 | 90 – 96 | Ultra-thin type, suitable for exquisite color-printed packaging (e.g., cosmetic boxes). |

| F Flute | 0.6 – 0.9 | 2.0 – 2.5 | 120 – 140 | Extremely thin type, used for micro-electronic product packaging. |

| B Flute | 2.2 – 2.9 | 4.5 – 5.0 | 50 – 54 | Universal type, commonly used for shipping cartons and internal dividers. |

| C Flute | 3.4 – 3.8 | 7.0 – 7.8 | 38 – 42 | Excellent cushioning performance; the mainstream choice for logistics packaging. |

| A Flute | 4.5 – 5.0 | 8.5 – 9.5 | 32 – 36 | Heavy-duty packaging, ideal for high load-bearing requirements. |

| AA Flute | 6.0 – 6.5 | 10.0 – 11.0 | 24 – 28 | Super load-bearing strength, used for industrial equipment packaging. |

| BC Flute | 5.6 – 6.2 | 7.5 – 8.5 | 42 – 46 | B+C combination, balancing overall strength and cushioning properties. |

| AB Flute | 6.3 – 6.8 | 6.5 – 7.5 | 50 – 54 | A+B combination, high compression-resistant composite structure. |

| AC Flute | 7.5 – 8.2 | 9.0 – 10.0 | 34 – 38 | A+C combination, used for heavy-duty shockproof packaging. |

| AAA Flute | 12.0 – 13.0 | 15.0 – 16.0 | 12 – 15 | Triple A composite, ultra-heavy-duty specialty packaging. |

| ACB Flute | 8.8 – 9.5 | 11.0 – 12.0 | 28 – 32 | A+C+B triple-layer composite for extreme protection needs. |

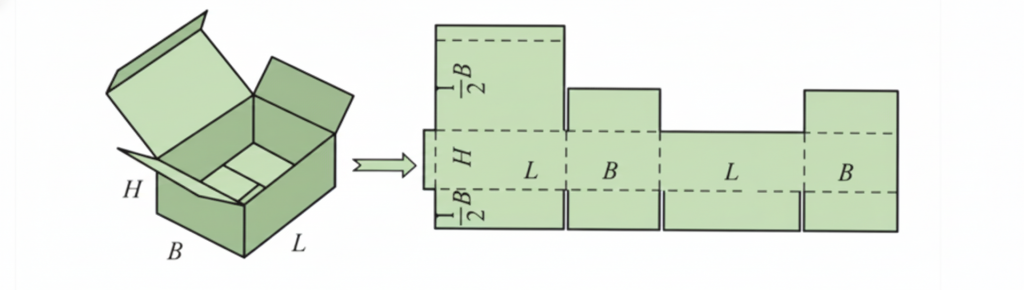

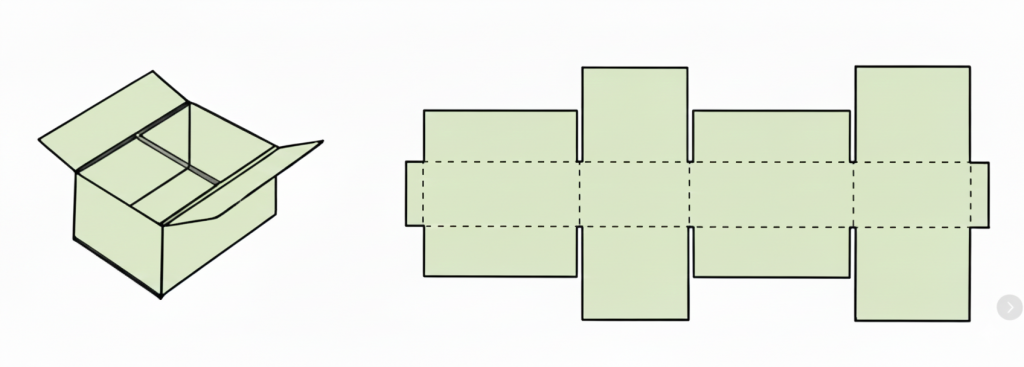

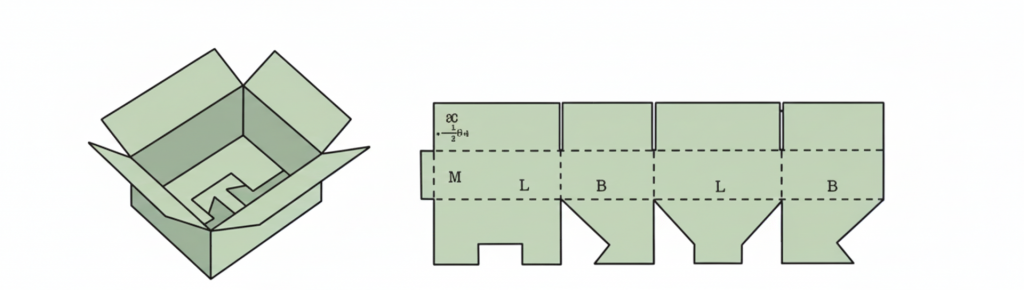

5.What types of corrugated box structures are there?

How to Choose the Right Size E Ecommerce Box for Products?

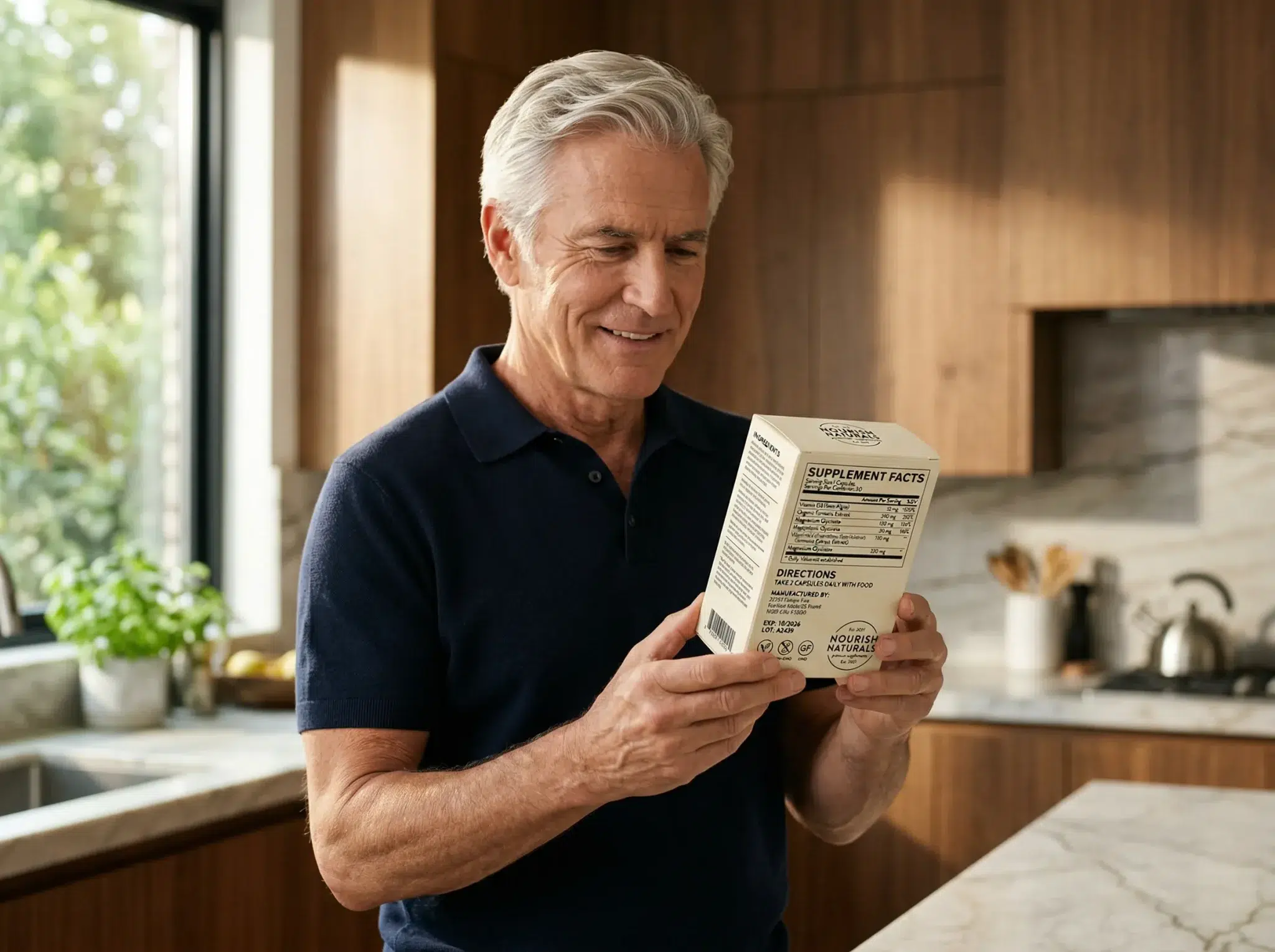

In the fast-paced world of e-commerce, cardboard box dimensions are far from “one size fits all.” Selecting the right packaging is a critical decision that balances product safety, brand perception, and the bottom line. Businesses must carefully evaluate their options based on product characteristics, logistics overhead, and warehousing efficiency.

Beyond the traditional shipping carton, the mailer box has emerged as a favorite for Direct-to-Consumer (DTC) brands. These boxes are designed with interlocking flaps that require no adhesive tape to close, providing a premium “unboxing” experience while offering superior structural integrity for smaller, high-value items like electronics, cosmetics, or subscription kits.

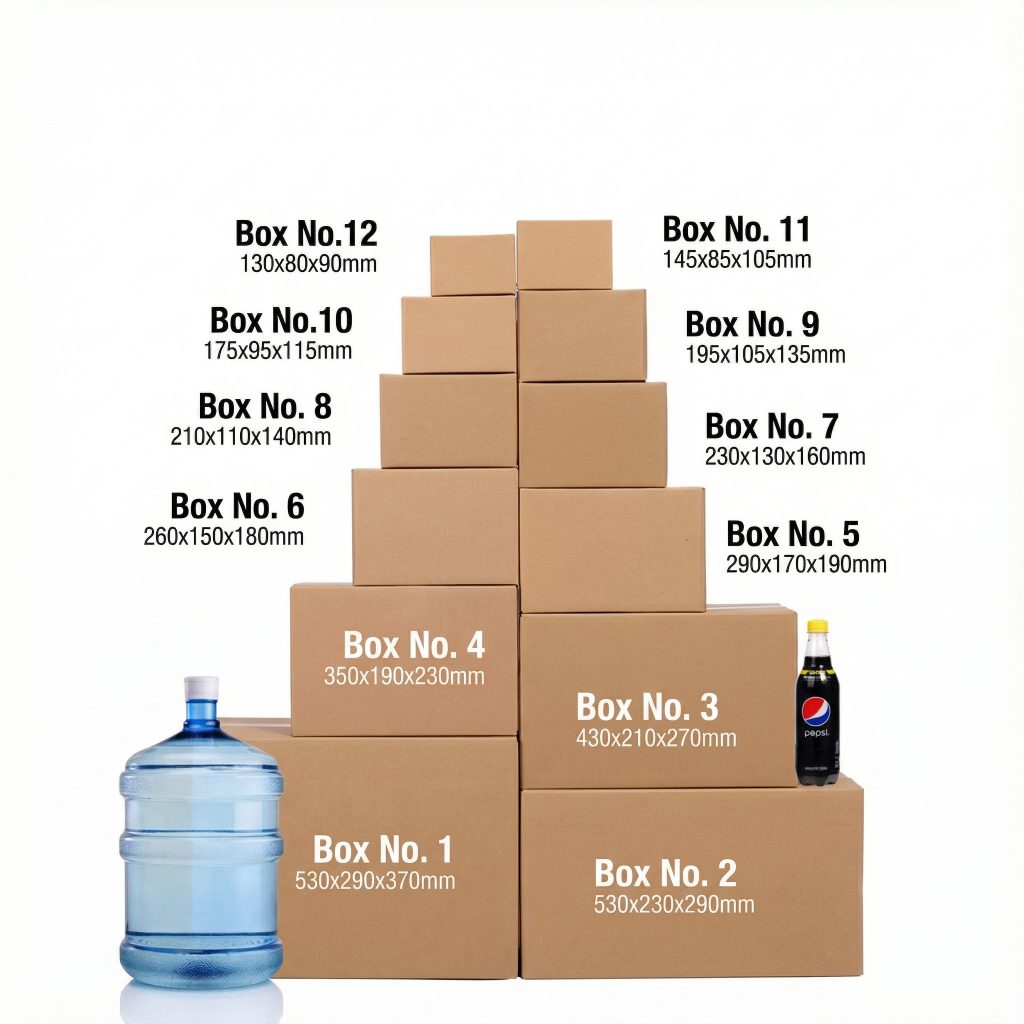

Standard E-commerce Shipping Box Size Chart

| Model | Dimensions (L*W*H mm) | Application Range |

|---|---|---|

| 12# | 130*80*90 | Small items: lipstick, small accessories, canned cola, normal mouse, face cream. |

| 11# | 145*85*105 | Small items: perfume, soap, small hand cream. |

| 10# | 175*95*115 | Small items: toner, phone case, small tissue box. |

| 9# | 195*105*135 | Medium items: 280ml thermos, facial cleanser, narrow facial masks. |

| 8# | 210*110*140 | Normal size items: facial masks, CD, glasses case. |

| 7# | 230*130*160 | Normal size items: most cosmetics, cup, 150m tape. |

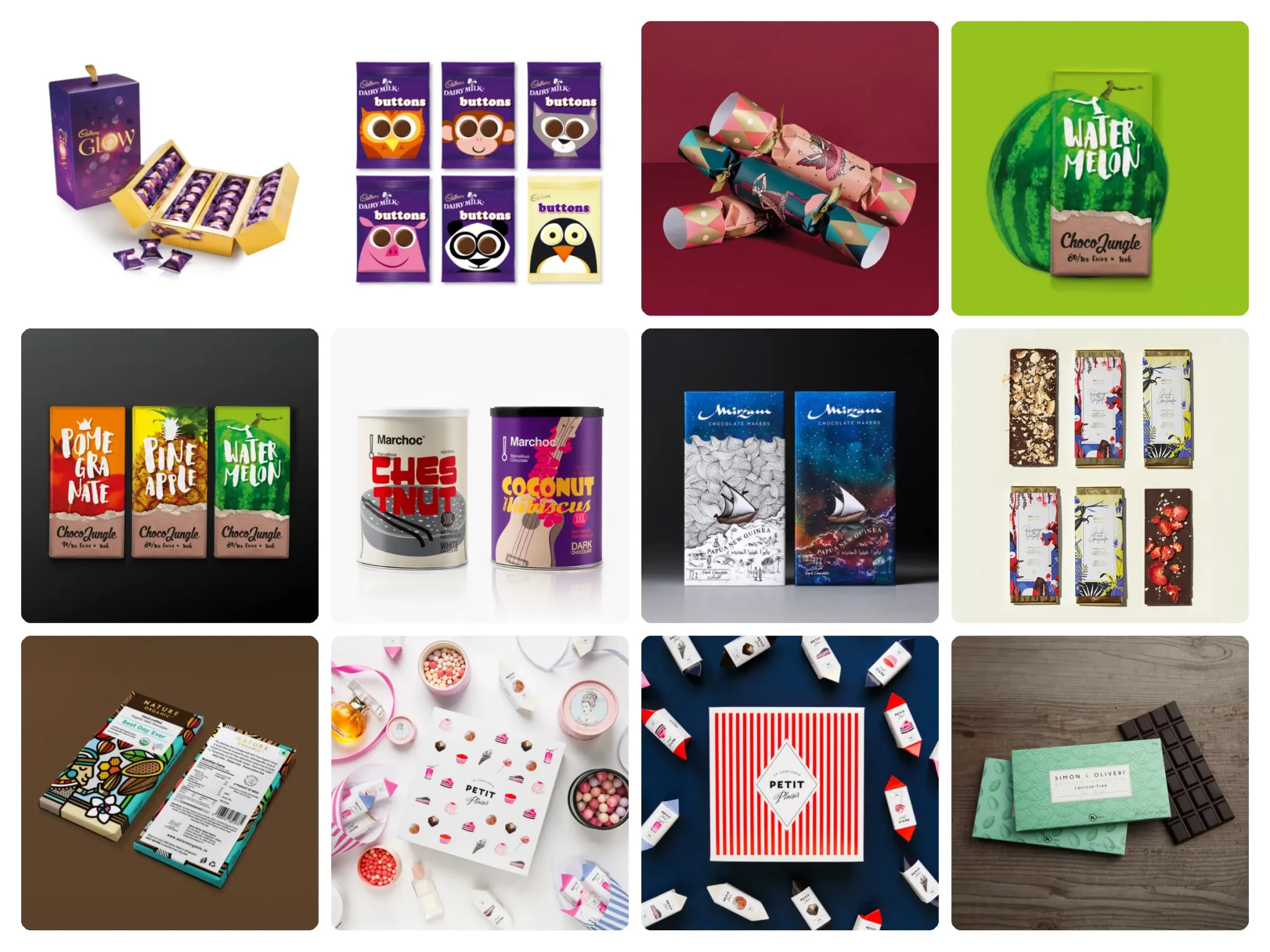

| 6# | 260*150*180 | Approx. 3 catties: snacks, canned milk powder, large pack masks. |

| 5# | 290*170*190 | Approx. 5 catties: small clothes, two cup noodles, magazines. |

| 4# | 350*190*230 | Approx. 10 catties: medium bags, hand warmer pillow, shoes. |

| 3# | 430*210*270 | Approx. 15 catties: fruit, bags and shoes. |

| 2# | 530*230*290 | Approx. 20 catties: air conditioning quilt, thin blanket, A4 paper. |

| 1# | 530*290*370 | Large items: computer tower (unboxed), one monitor. |

How to Measure the Outer Dimensions of a Shipping Box for Your Products?

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

30 Honey Packaging Designs That Capture Nature’s Sweetness

Why AI Packaging Design Makes Your Brand Faster