Things You Should Know About Winter Packaging And Printing

Winter is coming, and a large area of cooling is coming. In addition to the impact on people’s travel, the production of custom packaging and printing enterprises is also affected by the low-temperature weather. So, in this cold weather, what details should packaging and printing people pay attention to?

Things You Should Know About Winter Packaging And Printing

1. Prevent rotary offset printing ink from thickening in cold weather

For printing ink, if the room temperature and the liquid temperature of printing ink change significantly, the ink migration state will change, and the color will also change. At the same time, the low-temperature weather will have a significant impact on the ink transfer rate in the high-light areas. Therefore, when printing high-grade products, the temperature and humidity of the printing workshop should be controlled in any case. In addition, the ink should be preheated in advance when it is used in winter to reduce the temperature change of the ink itself.

Note that the ink is too thick at low temperatures, and the viscosity is also large, but it is better not to adjust its viscosity with thinner or inking oil. Because when users need to mix ink properties, the total amount of various additives that can be contained in the raw ink produced by the ink manufacturer is limited. If the amount exceeds the limit, even if it can be used, it will weaken the basic performance of the ink and affect the printing quality and printing technology.

The ink thickening caused by temperature can be solved by the following methods:

(1) Place the original ink on the radiator or beside the heater, and make it slowly warm up and gradually return to its original state.

(2) In case of emergency, use boiled water for external heating. The specific method is to pour the boiled water into the basin, and then put the original barrel (box) of ink in the water, but prevent the water vapor from being immersed. When the water temperature drops to about 27 ℃, take it out, open the lid and stir it evenly before use. The temperature of the printing workshop should be kept at about 27 ℃.

2. Pay attention to the use of antifreeze UV varnish

UV varnish is also a kind of material that is easily affected by low temperatures. Therefore, many suppliers specialize in producing two different formulas: winter type and summer type. The formula in winter has a lower solid content than that in summer, which can make the leveling performance of the varnish better when the temperature is low.

Note that if the winter formula is used in summer, it is easy to cause incomplete oil curing and anti-sticking; On the contrary, if the formula of summer is used in winter, the leveling performance of UV oil will be poor, resulting in blistering and orange peel failure.

3. Impact of low-temperature weather on paper

In printing production, paper is one of the consumables with high requirements on environmental temperature and humidity. Paper is a porous material, and its basic structure is composed of plant fibers and auxiliary materials. It has strong hydrophilicity. If the environmental temperature and humidity are not well controlled, it will cause paper deformation and affect normal printing. Therefore, maintaining the appropriate environmental temperature and humidity is the key to improving the quality of paper prints and improving production efficiency.

The requirements for an ambient temperature of ordinary paper are not so obvious, but when the ambient temperature is lower than 10 ℃, the ordinary paper will become very “brittle”, and the adhesion of the ink layer on its surface will decline during printing, which is easy to cause deinking.

Gold and silver card paper is usually made of coated paper, whiteboard, white card paper, and other substrates, and then compounded with PET film or aluminum foil and other materials. Gold and silver card paper has higher requirements on the ambient temperature because both metal and plastic materials are very sensitive to temperature changes. When the ambient temperature is lower than 10 ℃, the suitability of gold and silver card paper will be greatly affected. When the storage ambient temperature of gold and silver card paper is around 0 ℃, after it is transported from the paper warehouse to the printing workshop, a large amount of water vapor will appear on its surface due to temperature difference, affecting normal printing, and even leading to waste products. If the above problems are encountered, and the delivery date is tight, the staff can first turn on the UV lamp to let the paper run through the air, so that its temperature is balanced with the ambient temperature before formal printing.

In addition, low-temperature drying, low relative humidity, moisture exchange between paper and air, paper drying, warping, and shrinkage, will cause poor overprint.

4. Effect of low temperature on glue adhesive

The adhesive is an important chemical agent in industrial production, and its performance directly affects the quality of industrial products. An important technical index in adhesive production is temperature control. The raw materials of adhesives are mostly organic polymers, which are highly temperature dependent, which means that their mechanical properties and viscoelasticity are affected by temperature changes. It should be pointed out that low temperature is the culprit of the false adhesion of glue.

When the temperature drops, the hardness of the adhesive hardens, changing the stress effect at the adhesive. In the opposite low-temperature state, the movement of the polymer chain in the adhesive is limited, reducing the flexibility of the adhesive.

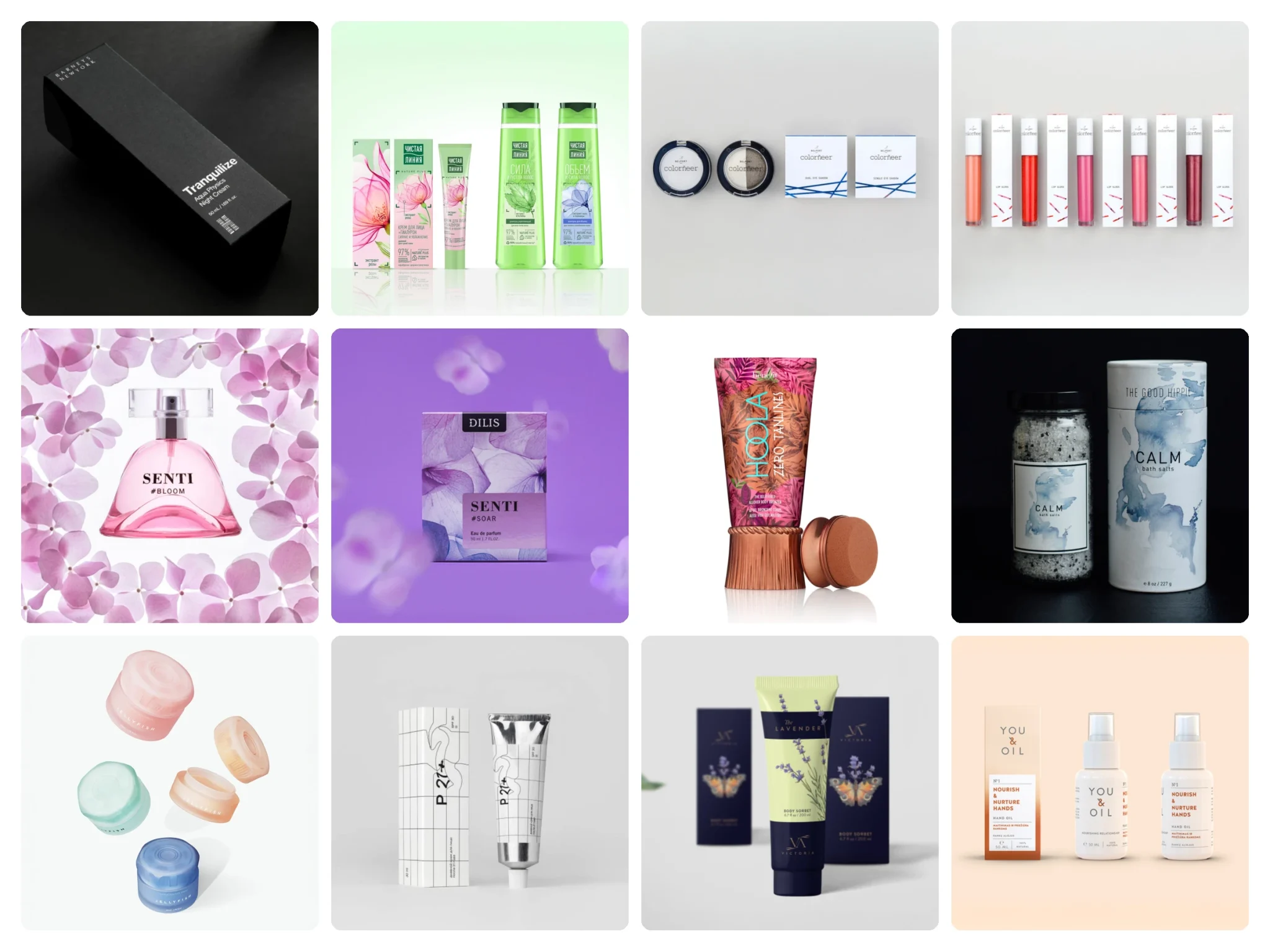

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

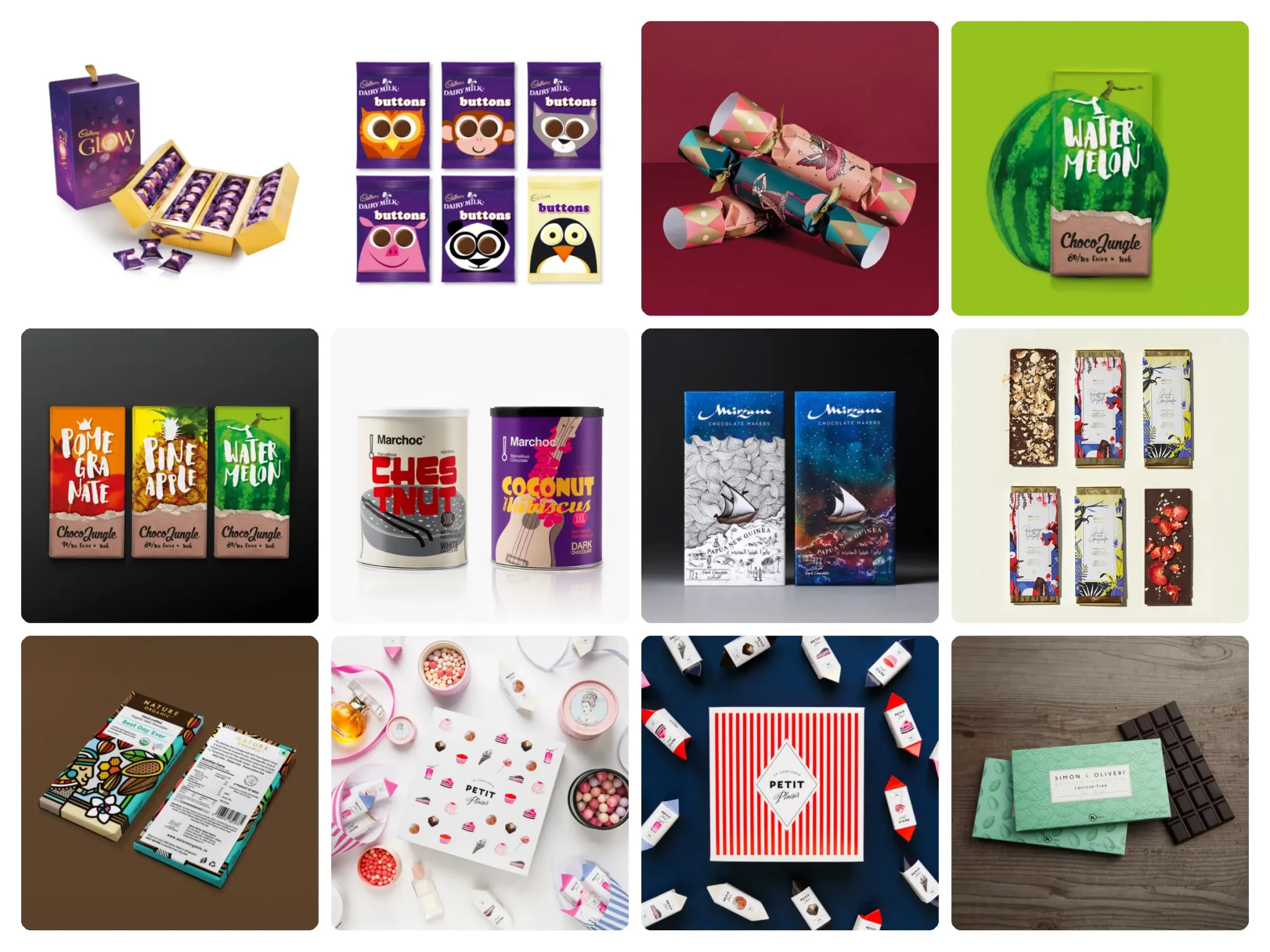

30 Honey Packaging Designs That Capture Nature’s Sweetness