What is Reverse UV Printing? Reverse UV Principle, Process, Material Requirements & Advantages

The reverse UV process can form different effects of high gloss and sand on the surface of printed materials. It reduces the surface treatment process and procedures of printed materials, which can be completed once by a printing machine, saving the processing and production time of lamination. Reverse UV varnishing and can achieve the contrast effect of ordinary varnishing can not do, can make the printing effect of the print better, more exquisite, printing quality to a higher level. This article shall describe the content of the reverse UV process for your reference:

1. What is Reverse UV Printing?

Reverse varnishing aka Pro-Cure is relative to traditional partial varnishing. In Europe and the United States, printers not only use the light-curing UV process to print the same quality as the traditional UV ink, and not satisfied with its high gloss mirror effect or transparent effect only, further improving the process and developed the Pro-Cure process to achieve a higher printing contrast effect.

The use of the Pro-Cure UV process can make the same print with both mirror high gloss effect and matte or linen non-high gloss effect, forming a stronger contrast in brightness and making the varnishing achieve better results. At the same time, because the non-glossy parts are printed by offset printing, the overprinting is very accurate, which also ensures the printing accuracy of the graphics on the glossy parts.

In general, Pro-Cure reverse UV printing solves the key problems in the ordinary varnishing process, and can achieve the contrast effect that ordinary varnishing can not do, can make the print better, more exquisite, the printing quality to a higher level.

2. Reverse UV Printing Work Principle

Using the “mutual exclusion” principle of coating-type UV Varnish and bottom-printing UV varnish (ink fountain-type UV Varnish), the effect of concave-convex texture and different gloss can be realized at one time, that is, coating varnish on the place without primer to achieve Glossy effect, after applying varnish on the place with primer, it can achieve a matte effect. This process can realize the change of light and shade (or wrinkle shrinkage strength) after UV glazing by controlling the amount of UV primer or the size of dots.

There are three main recommended printing sequences for the reverse varnishing process.

(1) UV color ink printing a UV irradiation curing a UV primer printing a UV irradiation curing a UV light varnish coating a UV irradiation curing.

(2) UV color ink printing a UV irradiation curing a UV base varnish printing a UV light oil coating a UV irradiation curing (no irradiation in between).

(3) UV color ink printing a UV irradiation curing + (offline secondary printing) + UV base varnish printing a UV light oil coating an I-JV irradiation curing.

3. Material Requirements For Reverse UV Printing

- Smoothness – Choosing paper with high surface smoothness, paper quality or surface roughness, and oil absorption, will reduce the gloss of the printed surface so that the varnishing effect is not obvious.

- Amount of Spray Powder – Such as for the choice of ordinary ink printing documents, it is recommended that the inline varnishing process does not use spray powder, but also offline coating water-based varnish. Printed material sprayed powder is too much, affecting the formation of varnish mirror and particles without contrast, the effect is not strong.

- Ink Drying – Printing must be fully dried under the circumstances of surface treatment, in case of the ink layer is not dry may cause the varnish curing is not complete, with no effect.

- Pre-printing Production – Need to select the pattern for processing, the part of the frosting effect out of the selection, fill the solid base color, bright place empty, in the out of the film and publication single out.

- Absorbency – The choice of paper with poor surface absorption, absorbent paper varnish effect is not obvious

- Paper Material – Choose paper with good surface quality, the surface of the poor color coating, easy to storm color

- Additives – Reverse UV process products, generally add less UV curing agent, not more than 1% of the amount, which is not conducive to reverse UV effect

- Paper moisture content – Need to choose the right amount of water content of the material, high water content paper deformation curl, low water content paper dry easy to break

4. Reverse UV Printing Process

- Conventional printing must be completed before varnishing and make sure the ink has been thoroughly dried or cured.

- Then, the non-high gloss part of the design is printed with transparent reverse ink in offset mode in a continuous or offline manner.

- then inline, in a full-page manner on the printing surface coated with a UV varnish and cured.

- light oil and previously on the reverse ink contact, resulting in a cohesive reaction, in the non-high gloss parts of the formation of the small particle-like ink film, to achieve matte or linen effect. And not on the reverse ink on the high-gloss parts of the formation of mirror high-gloss effect

- the use of reverse varnishing process can make the same print on the same time there is a mirror high gloss effect and matte or linen non-high gloss effect, in the brightness of the formation of stronger contrast, so that the varnish to achieve better results. At the same time, because the non-high gloss parts are printed by offset printing, the overprinting is very accurate, which also ensures the printing accuracy of the high gloss parts of the graphics.

5. Reverse UV Printing Advantages

- High-contrast partial glazing of partial graphics and texts can be realized, and the accuracy of glazing and overprinting is the key to the glazing process.

- Enhance the light fastness of the ink, increase the heat resistance of the ink, increase the moisture resistance, protect the product, beautify the product, and can present two kinds of gloss and different processing.

6. UV Printing Process Identification

Reverse UV process, frosted UV process, frosted embossing process, screen printing small snowflake UV difference:

- Reverse UV process: the surface is bright, greasy feeling, and easy to scrape off the blade; is the printing UV process.

- Frosted UV process: the surface is a whitish effect, frosted feel, easy to scrape off with a razor blade; is the screen printing UV process.

- Frosted embossing process: the surface is a dark effect, and frosted feel, and can not be scraped off with a razor blade; is the embossing machine process.

The method of distinguishing three kinds of processes, such as reverse UV process, frosted UV process, and frosted embossing process:

First of all, scrape with a blade: scrape off for the reverse UV or frosted UV process; scrape off for the frosted embossing process.

The difference between reverse UV and frosted UV is to view the surface phenomenon: whitening effect, sandy feel, glossy not bright for the frosted UV process; the surface is bright, greasy feeling, is the reverse UV process.

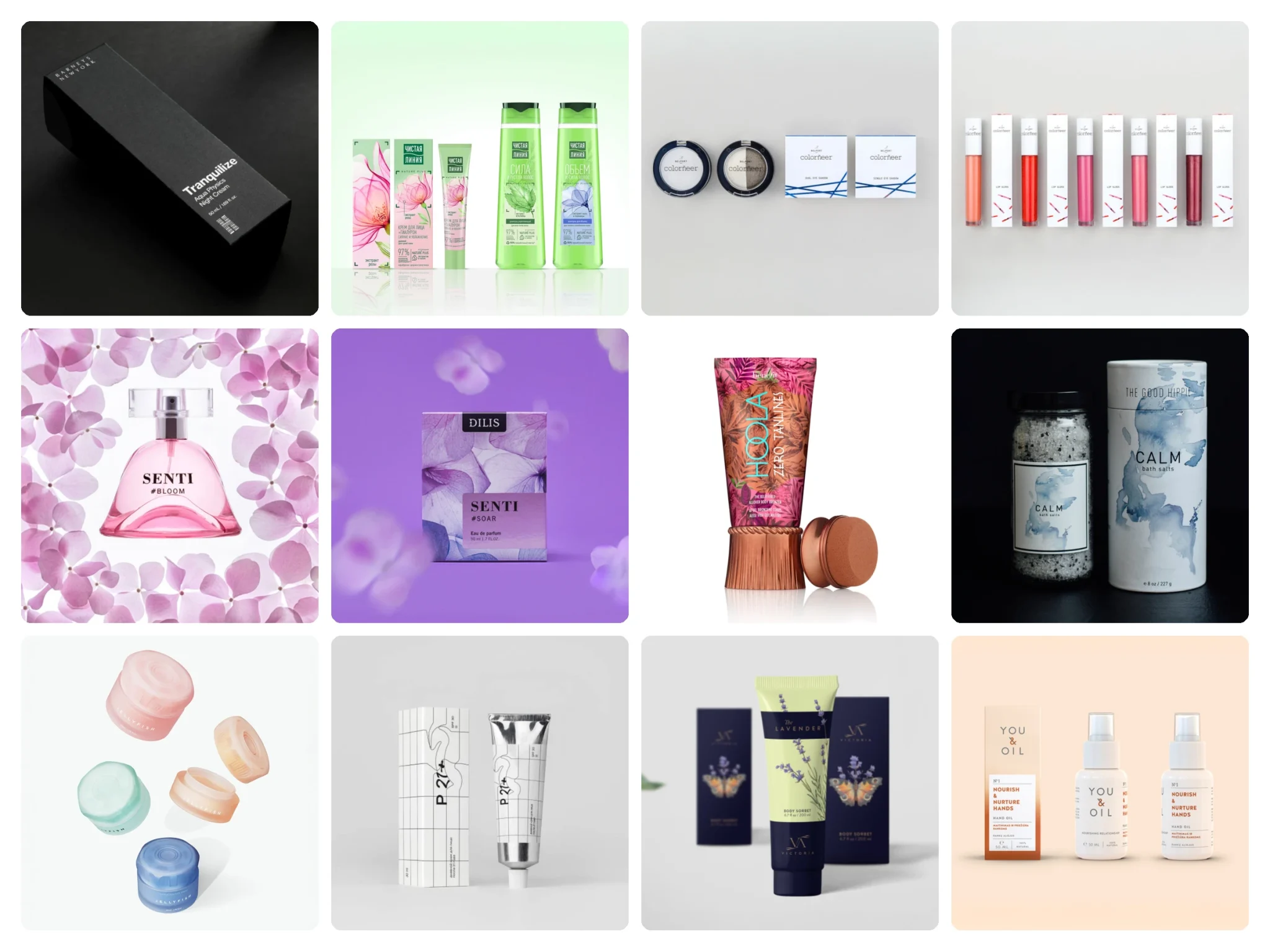

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

30 Honey Packaging Designs That Capture Nature’s Sweetness