Why Choose MDF Boxes Over Wooden Boxes?

Introduction

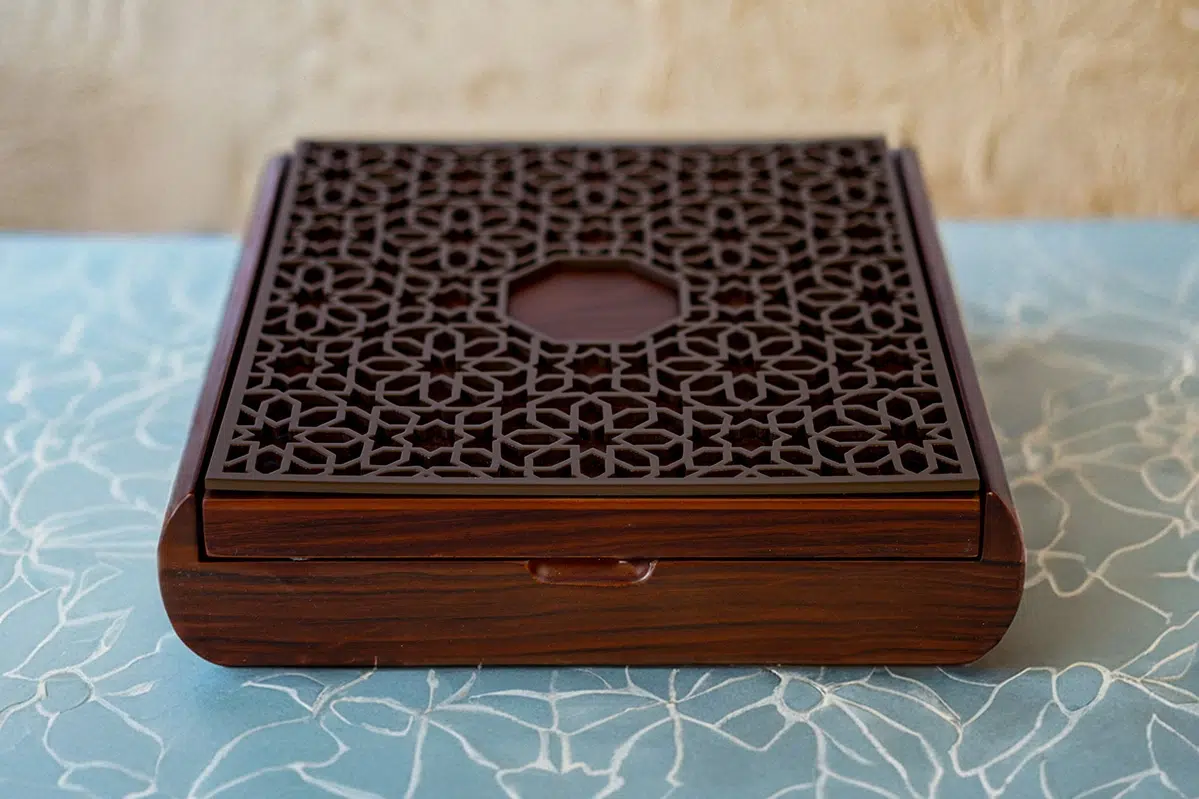

Have you know MDF box? Compared to wooden boxes, more companies are opting for MDF boxes when it comes to high-end packaging. The decision between MDF boxes and conventional wooden boxes has become a critical one for companies in the changing realm of packaging options. MDF gift boxes have become a better substitute for traditional hardwood packaging as sustainability and economy of cost take front stage.

The Modern Packaging Solution – MDF

Made from broken down hardwood or softwood residuals into wood fibers, MDF (medium-density fiberboard) boxes is an engineered wood product. Dense, strong panels are produced by mixing these fibers with wax and resin under high temperature and pressure.

MDF Boxes vs. Wood Boxes

| Features | MDF Boxes | Wooden Boxes |

|---|---|---|

| Cost per unit | More budget-friendly compared to wood | Higher cost due to premium materials |

| Surface finish | Smooth & consistent | Variable & grainy |

| Weight | Lighter (30% less) | Heavier |

| Customization | Highly flexible | Limited |

| Environmental impact | Recyclable | Partially recyclable |

| Durability | High resistance to warping | Prone to warping |

| Policy Impact | Widely accepted (eco-compliant) | Banned in some countries |

Contact our to discover how MDF boxes can enhance your products!

Key Advantages of MDF Boxes

1. Superior Cost-Effectiveness

Two main benefits of MDF Boxes are exceptional cost-effectiveness. MDF boxes are more affordable for companies since their prices usually range 30–40% cheaper than those of conventional wooden boxes. The more efficient production process produces:

-

Reducing material expenses

-

Shortened production times

-

More consistent output of quality

2. Enhanced Design Flexibility

MDF gift box provide better possibilities for personalizing:

-

Perfect surface for top printing

-

Simple shape and cutting

-

Consistent premium finishes’ texture

-

Enhanced paint adhesion

3. Environmental Benefits

Current MDF manufacturing stresses environmental sustainability:

-

Makes use of reclaimed wood fibers

-

Calls for less raw material than solid wood.

-

Reduce manufacturing’s carbon footprint

-

Completely recyclable final result

Quality and Performance Features

Surface Quality

MDF’s homogeneous density offers very special benefits:

-

No knots or grain patterns that can affect finishing

-

Consistent surface for luxury packaging

-

Better paint and laminate adhesion

-

Superior printing results

Structural Stability

MDF boxes demonstrate excellent structural properties:

-

Resistant to warping and splitting

-

Consistent density throughout

-

Better screw-holding capability

-

Dimensional stability in varying conditions

Industry Applications and Success Stories

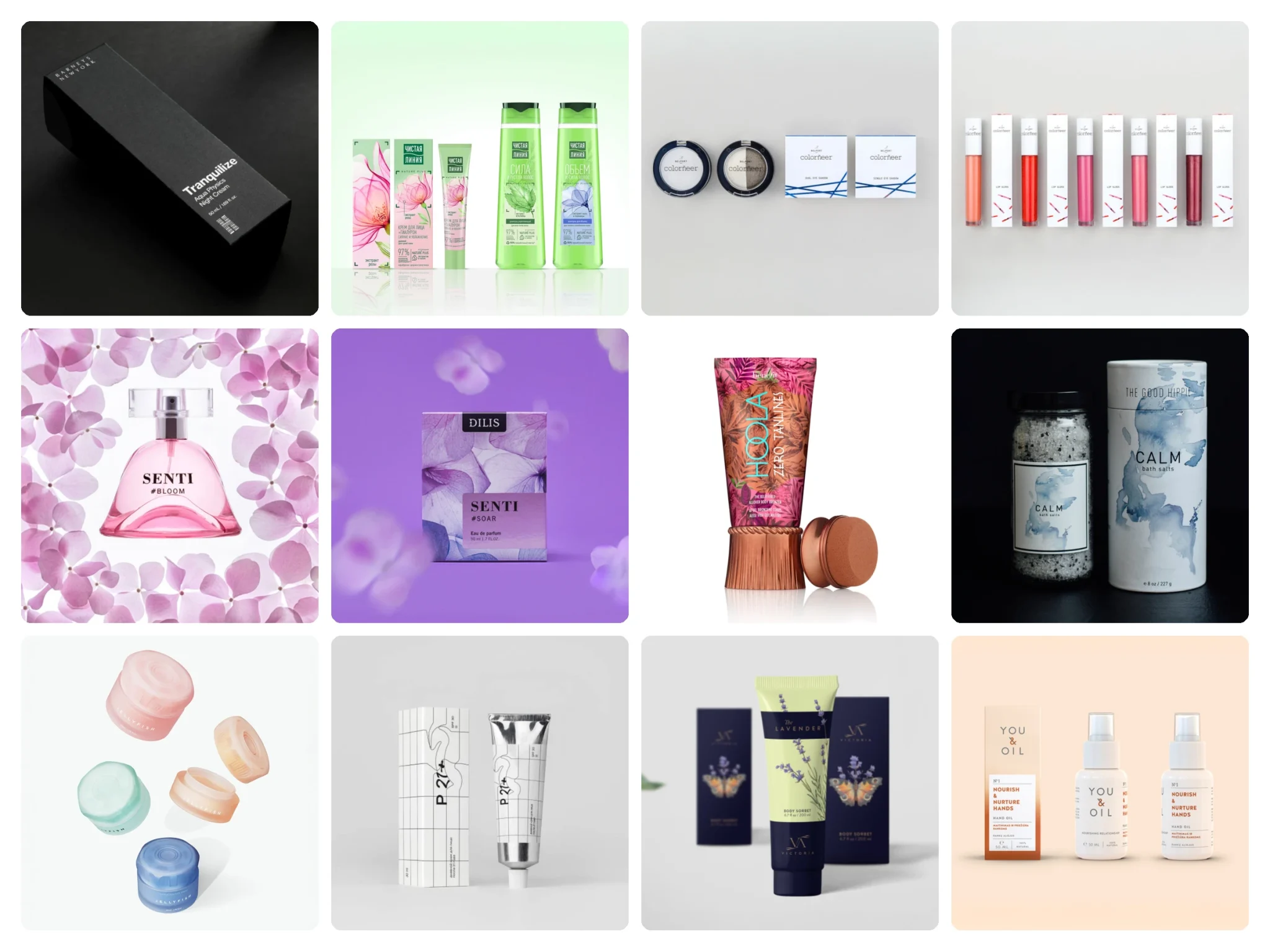

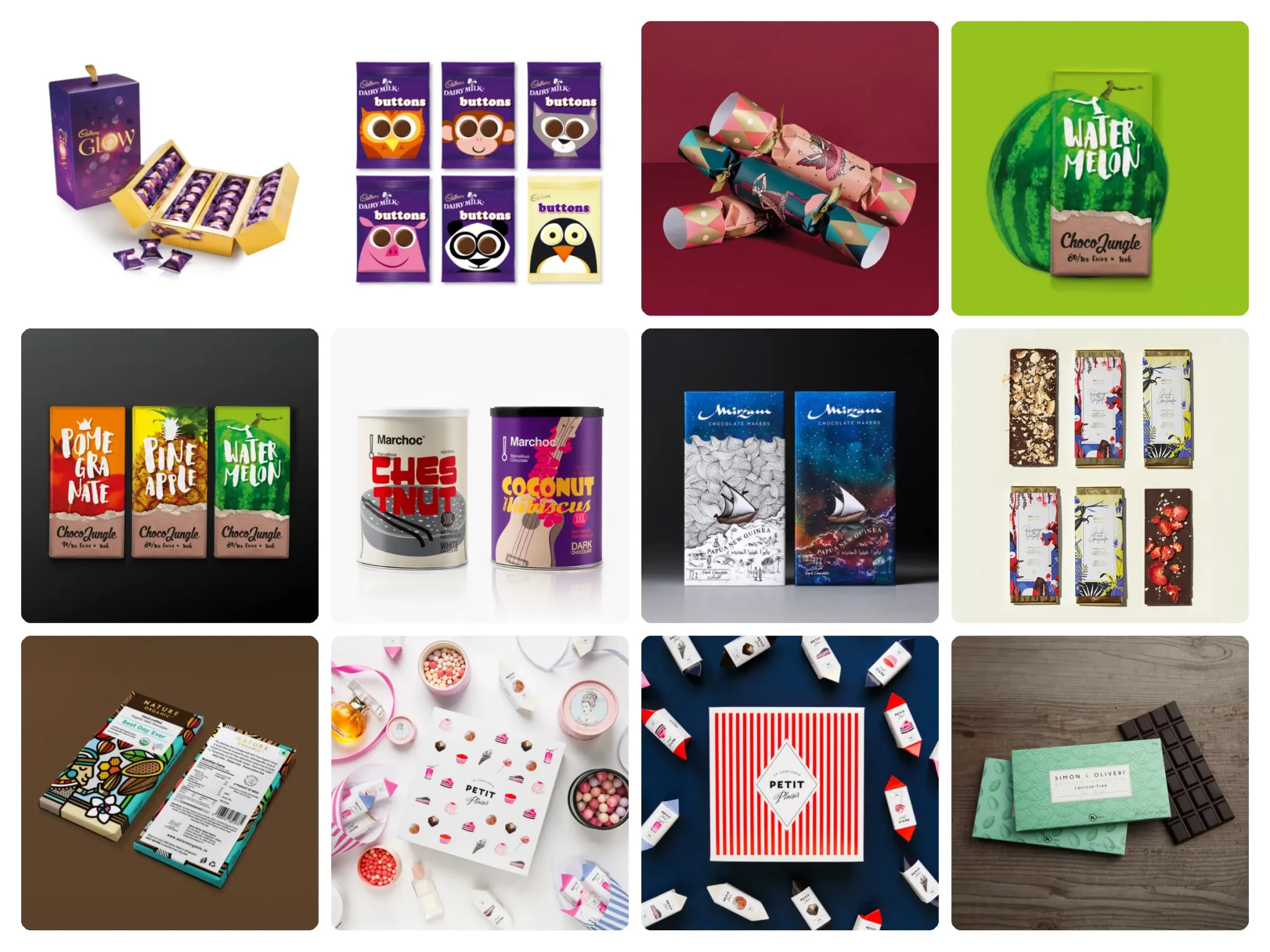

Luxury Packaging Sector

Leading brands increasingly choose MDF for premium packaging:

-

Jewelry boxes

-

Wine packaging

-

Premium gift sets

-

Cosmetic packaging

Future Trends and Innovation

Emerging Technologies

The MDF packaging industry continues to evolve with:

-

Advanced coating technologies

-

Improved water resistance

-

Enhanced durability features

-

Innovative design capabilities

Conclusion

MDF boxes clearly provide more creative opportunities, greater value, and higher green credentials than traditional hardwood packaging. While the material’s adaptability permits amazing unique designs that improve brand presentation, their great cost-efficiency helps companies to lower expenses without sacrificing quality. Changing to MDF packaging puts your brand front and front as consumer desire for both sustainable practices and quality unboxing events rises.

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

30 Honey Packaging Designs That Capture Nature’s Sweetness