Characteristics of 11 Plastic Films For Packaging Bags

As a printing material, plastic film, as a packaging bag after printing, has the advantages of lightness and transparency, moisture and oxygen resistance, good air tightness, toughness and folding resistance, smooth surface, protection of goods, and reproduction of the shape and color of goods. With the development of petrochemical industry, there are more and more varieties of plastic films. Common plastic films include polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), polyester film (PET), polypropylene (PP), nylon (PA), etc. In addition, there are many other types of plastic films. Shunxingyuan Packaging, a professional flexible packaging manufacturer, believes that it is necessary to understand the characteristics of plastic films before customizing packaging bags. Today, it specially collates the characteristics of 11 types of plastic films in the lower packaging bags for your reference.

1. Polyvinyl chloride (PVC)

The advantages of PVC film and PET are similar, both of which are transparent, impermeable, and acid and alkali resistant. In the early days, many food packaging bags were made of PVC. However, PVC may release carcinogens due to incomplete polymerization of some monomers during the manufacturing process, so it is not suitable for filling food-grade substances. At present, most of them have changed to using PET packaging bags with the material symbol No. 3.

2. Polystyrene (PS)

PS film has low water absorption, but its size stability is good. It can be processed by shooting, pressing, extrusion, and thermoforming. Generally, it is divided into foaming and nonfoaming according to whether it has gone through the foaming process. Unformed PS is mainly used in building materials, toys, stationery, etc. It can also be commonly made into containers to fill fermented dairy products (such as Yakult, Health&Fitness, Duoduo and other dairy products or lactic acid products). In recent years, it is also widely used to make disposable tableware, with the material symbol of No. 6.

3. Polypropylene (PP)

Ordinary PP film is formed by blow molding with a simple process and low cost, but its optical properties are slightly lower than those of CPP and BOPP. PP is characterized by high-temperature resistance (about – 20 ℃~120 ℃) and a melting point as high as 167 ℃. It is suitable for filling soybean milk, rice milk, and other products requiring steam sterilization. Its hardness is higher than that of PE, and it is mostly used to manufacture container caps. The material symbol is No. 5. Identification method: Generally speaking, PP has a high hardness, a shiny surface, and no irritating smell when burning, while PE has a heavy candle smell.

4. Polyester film (PET)

Polyester film (PET) is a thermoplastic engineering plastic. The film material is made of thick sheets by an extrusion method and then biaxial stretching. Polyester film is characterized by excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, high and low-temperature resistance, chemical resistance, oil resistance, air tightness, and fragrance retention. It is one of the commonly used barrier composite film substrates, but has poor corona resistance and a high price. The film thickness is generally 0.12 mm. It is usually used as the outer layer material of food packaging bags and has good printability. The material symbol marked in the plastic products is No. 1.

5. Nylon (PA)

At present, there are many varieties of nylon plastic film (polyamide PA) produced industrially, including nylon 6, nylon 12, nylon 66, etc. Nylon film is a very tough film with good transparency and luster. The tensile strength, tensile strength, high and low-temperature resistance, oil resistance, organic solvent resistance, abrasion resistance, and puncture resistance are all very good, and the film is relatively soft, with excellent oxygen resistance, but it has poor water vapor barrier, large moisture absorption, moisture permeability, and poor heat sealing. It is suitable for packaging hard goods, such as greasy food, fried food, vacuum packaged food, cooked food, etc.

6. High density polyethylene (HDPE)

HDPE membrane is called geomembrane or impermeable membrane. Its melting point is about 110 ℃ – 130 ℃, and its relative density is 0.918-0.965kg/cm3. It is a kind of high crystallinity, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. It has good high and low-temperature resistance and impacts resistance, even at – 40F low temperature. Its chemical stability, rigidity, toughness, mechanical strength, and tear resistance are excellent. With the increase of density, its mechanical properties, barrier properties, tensile strength, and heat resistance will be improved accordingly, and it can resist acid, alkali, organic solvent, and other corrosion. Identification method: Most of them are opaque and feel like wax. There is a rustle when the plastic bag is rubbed or rubbed.

7. Low density polyethylene (LDPE)

LDPE film has low density, softness, low-temperature resistance, impact resistance, and good chemical stability. It is generally resistant to acid (except strong oxidizing acid), alkali, and salt corrosion and has good electrical insulation. LDPE is mostly used in plastic packaging bags with the material symbol No. 4. Its products are mostly used in civil engineering and agricultural fields, such as geomembrane, and agricultural film (greenhouse film, mulching film, green storage film, etc.). Identification method: The plastic bag made of LDPE is relatively soft and will not make rustle when kneading. The plastic film of the outer package is soft and easy to tear, while the plastic film of PVC or PP is brittle and hard.

8. Polyvinyl alcohol (PVA)

Polyvinyl alcohol (PVA) high barrier composite film is a film with high barrier properties formed by coating modified polyvinyl alcohol water-soluble liquid on the base material with polyethylene plastic as the base material. Because PVA high barrier composite film has good barrier performance and meets the requirements of environmental protection, the market prospect of this kind of packaging material is very bright and has broad market space in the food industry.

9. Cast polypropylene film (CPP)

Cast polypropylene film (CPP) is a kind of non-stretching and nonoriented flat extruded film produced by melt casting quenching. It is characterized by fast production speed, high output, good transparency, luster, barrier, softness and thickness uniformity of the film, high-temperature cooking resistance (cooking temperature above 120 ℃) and low-temperature heat sealing (heat sealing temperature below 125 ℃), and excellent performance balance. Subsequent work such as printing and compounding is convenient and is widely used in the packaging of textiles, food, and daily necessities. As the inner substrate of composite packaging, it can extend the shelf life of food and increase its aesthetics.

10. Biaxially oriented polypropylene film (BOPP)

Biaxially oriented polypropylene film (BOPP) is a transparent soft packaging bag material developed in the 1960s. It is a special production line that mixes polypropylene raw materials and functional additives, melts and mixes them into sheets, and then makes films by stretching. This kind of film not only has the original advantages of PP resin, such as low density, good corrosion resistance, and heat resistance but also has good optical properties, high mechanical strength, rich sources of raw materials, excellent printing properties, and can be compounded with paper, PET and other substrates, high definition and glossiness, excellent ink absorption and coating adhesion, high tensile strength, excellent oil barrier performance, low static characteristics, etc.

11. Aluminizing

The aluminized film has the characteristics of both plastic film and metal. The role of aluminum plating on the film surface is to block light and prevent ultraviolet radiation, which not only extends the shelf life of the contents, but also improves the brightness of the film, replacing aluminum foil to a certain extent, and also has cheap, beautiful and good barrier performance. Therefore, the aluminized film is widely used in composite packaging, mainly in the packaging of dry and puffed food such as biscuits, medicine, and cosmetics.

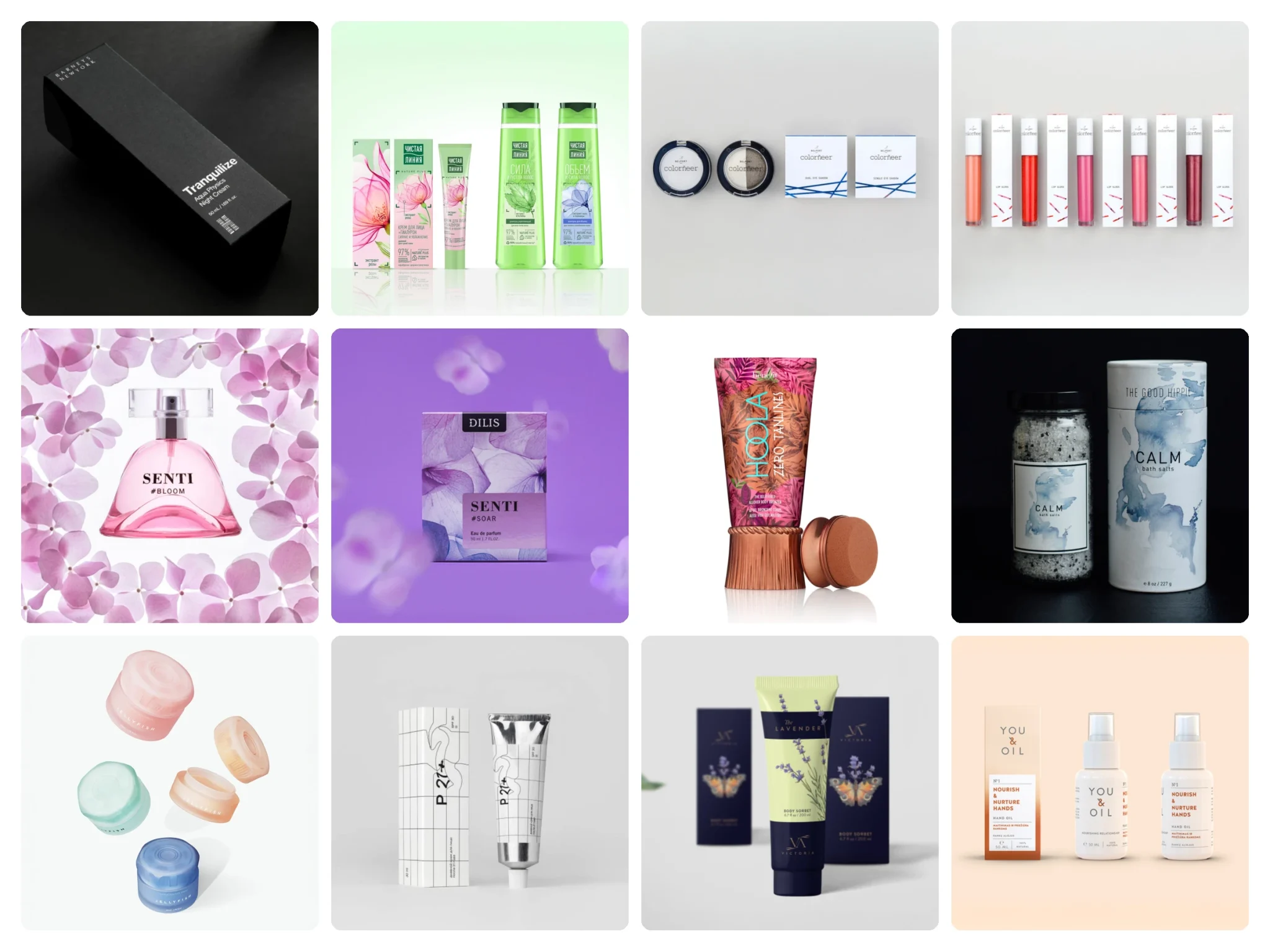

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

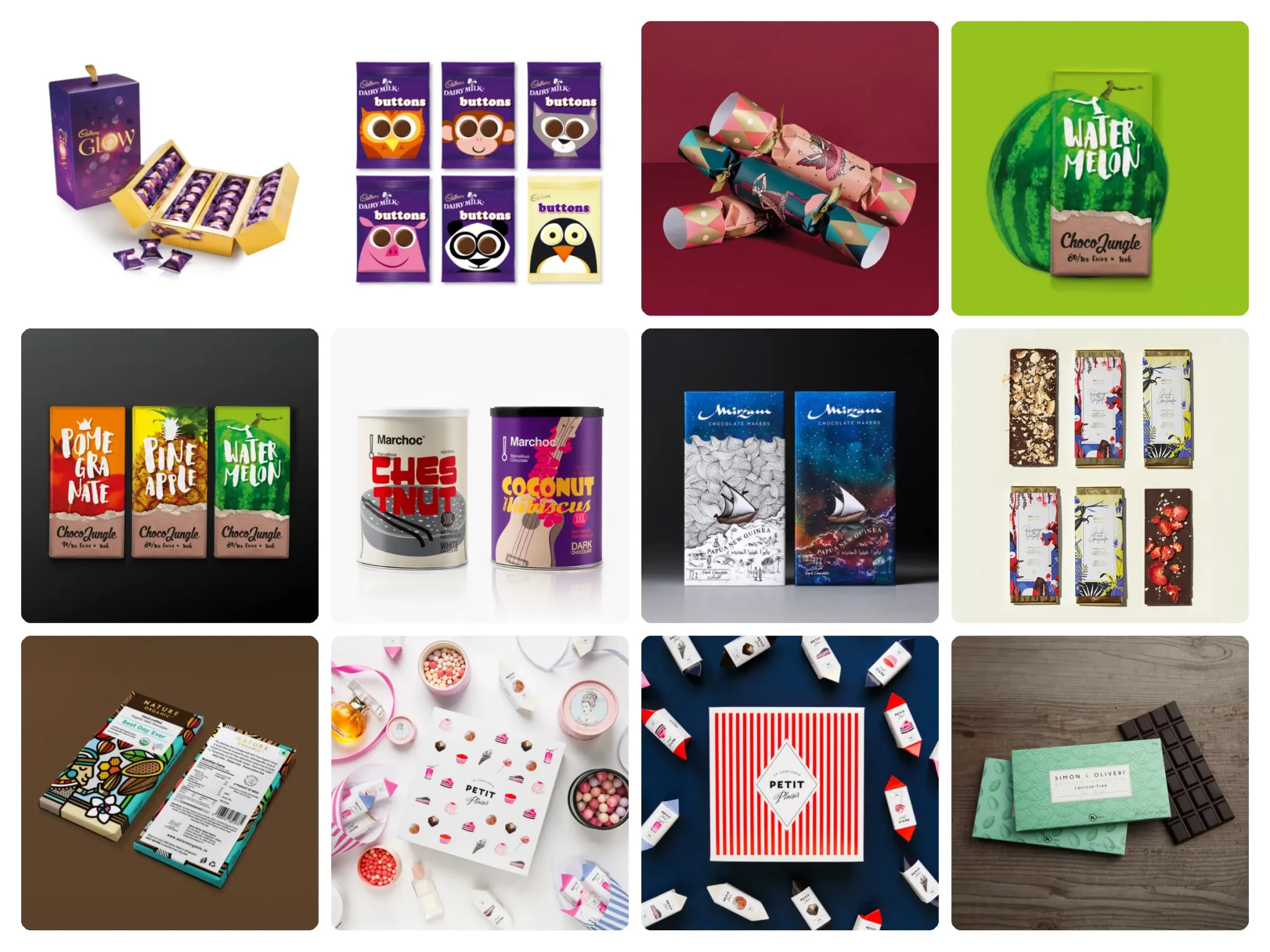

30 Honey Packaging Designs That Capture Nature’s Sweetness