Classification and Introduction of Packaging Structures & Materials

The packaging structure of commodities has many styles. On the one hand, the formation of packaging structure is based on the needs of commodities for packaging, including protective needs, sales needs, and display needs; On the other hand, it is also based on the characteristics of packaging materials, including their applicability and plasticity. Common packaging structures are divided into nine categories, and common packaging materials are divided into six categories. Next, let’s learn about them:

Classification and Introduction of Packaging Structures

TATA box

The box structure is mostly used for commodities in the solid state, which plays the role of protection, stacking, transportation, and so on. Most of the materials used are paper. In addition, they can also be made of plastic, bamboo, wood, metal, and other materials.

Tank structure

It is mostly used to pack goods mixed with liquid, liquid, and solid. It is characterized by good sealing, fresh preservation, and extended service life. Furthermore, it is mostly made of metal materials (including iron, aluminum alloy, etc.).

Bottle structure

It is mostly used for liquid packaging. The bottle cap is made of a wood stopper, metal, or plastic. Packaging materials are made of glass, ceramic, or plastic.

Bag structure

Bag structure is mostly used for packaging solid commodities. Common materials include cloth bags, gunny bags, woven bags, plastic bags, aluminum foil bags, paper bags, etc.

Basket structure

Basket structure is mostly used for comprehensive gift packaging. Different types of goods are packed in a carefully designed basket. The outside is wrapped with transparent plastic film or cellophane, and some decorative ribbons form a beautiful flower basket, which is suitable for gifts.

Bowl, disc, and cup structure

It is mostly used for food packaging. The container is made of plastic or hard paper, which is covered with paper, plastic or film, and contains food.

Sleeve structure

It is mostly used to protect goods, such as shoe covers, umbrella covers, mobile phone covers, etc. it is made of cloth, paper, plastic, etc.

Tubular structure

The pipe is mostly used for thick goods. It is made of a metal hose or plastic hose for extrusion. It is equipped with a nozzle and cap. Furthermore, it is used in the packaging of ointment, cosmetics, toothpaste, pigment, etc.

Blister structure

It is mostly used for the combination of transparent plastic and bottom plate, such as the packaging of tablets, hardware, electronic accessories, toothbrushes, toys, and so on.

Classification and Introduction of Packaging Materials

Paper packaging

In modern society, most packaging materials are paper products, and their consumption accounts for about 40% of the whole packaging materials. It occupies a major position in the packaging industry. Its biggest advantages are lightness, good hygiene, appropriate strength, easy bonding and printing, convenient mechanized production, easy material selection, low price, and so on. The disadvantages are low to tear strength and easy deformation. Paper packaging forms include cardboard boxes, corrugated boxes, cartons, paper bags, paper cylinders, paper cups, etc

Plastic packaging

All kinds of packaging made of plastic materials are collectively referred to. Commonly used plastic food materials include polyethylene, polypropylene, polyvinyl chloride, polystyrene, polyester, etc. Plastic packaging has the advantages of a lightweight, transparency, different strength and elasticity, convenient folding and sealing, waterproof, moisture-proof, anti-leakage, easy molding, good plasticity and airtightness, shockproof, anti-pressure, anti-collision, impact resistance, good chemical stability, easy coloring, printability, and low cost. However, plastics are difficult to degrade and easy to cause environmental pollution. The main packaging forms include plastic barrels, plastic hoses, plastic boxes, plastic bottles, plastic film, and plastic woven bags.

Wood packaging

Wood materials have been used by human beings for a long time. It is characterized by high strength, firmness, pressure resistance, impact resistance, stable chemical and physical properties, easy processing, and no environmental pollution. It is a common packaging material for large and heavy commodities. Wood packaging forms mainly include wooden boxes, barrels, wooden shafts, wooden boxes, wooden splints, fiber cartons, plywood paper, trays, etc. However, due to the small source of wood, other materials have been used to replace it.

Metal packaging

Common metals include black sheet iron, tinplate, steel plate, aluminum plate, aluminum alloy, aluminum foil, etc. It is characterized by firmness, collision resistance, airtightness, water tightness, compression resistance, and excellent mechanical strength. They mainly include metal barrels, metal boxes, cans, metal hoses, oil tanks, steel cylinders, etc. they are mostly used for the packaging of machines, liquids, powders, pastes, and other commodities.

Glass packaging

Glass is an inorganic silicate product, which mainly refers to the packaging of goods with acid-resistant glass bottles and acid-resistant ceramic bottles. Its characteristics are transparent, clean, beautiful, good mechanical properties and chemical stability, easy to close, cheap, reusable many times, and rich in resources. Common glass packaging containers include bottles, cans, jars, etc. Glass packaging is widely used in the sales and packaging of alcohol, beverages, cans, condiments, drugs, cosmetics, chemical reagents, and other commodities.

Fiber packaging

Fiber fabric packaging mainly includes baskets, baskets, and boxes made of tree strips, bamboo strips, and wickers, as well as straw purses and straw bags. It has the advantages of local materials, low cost, and good air permeability. It is suitable for packaging fresh commodities, some local products, and ceramic products.

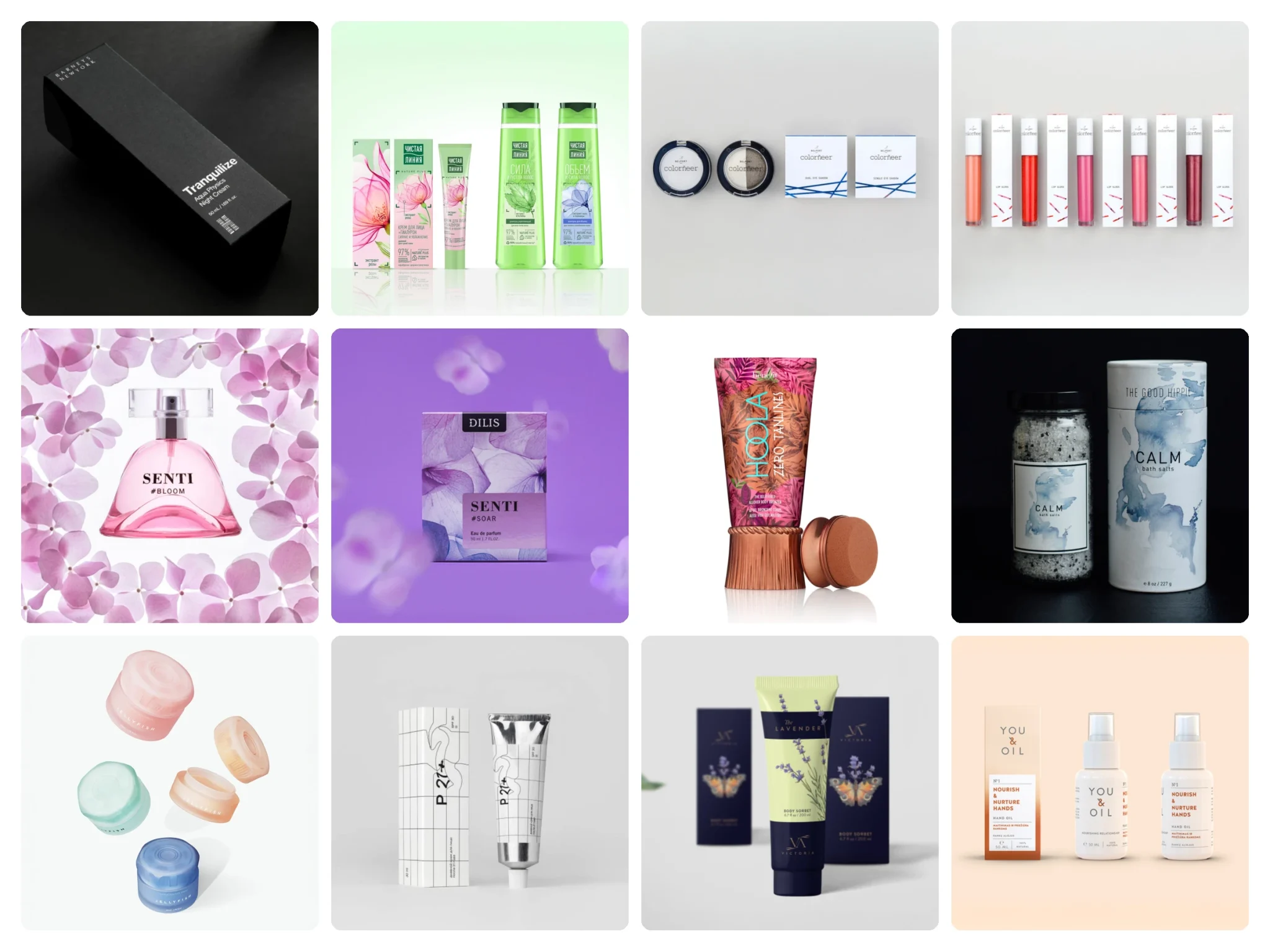

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

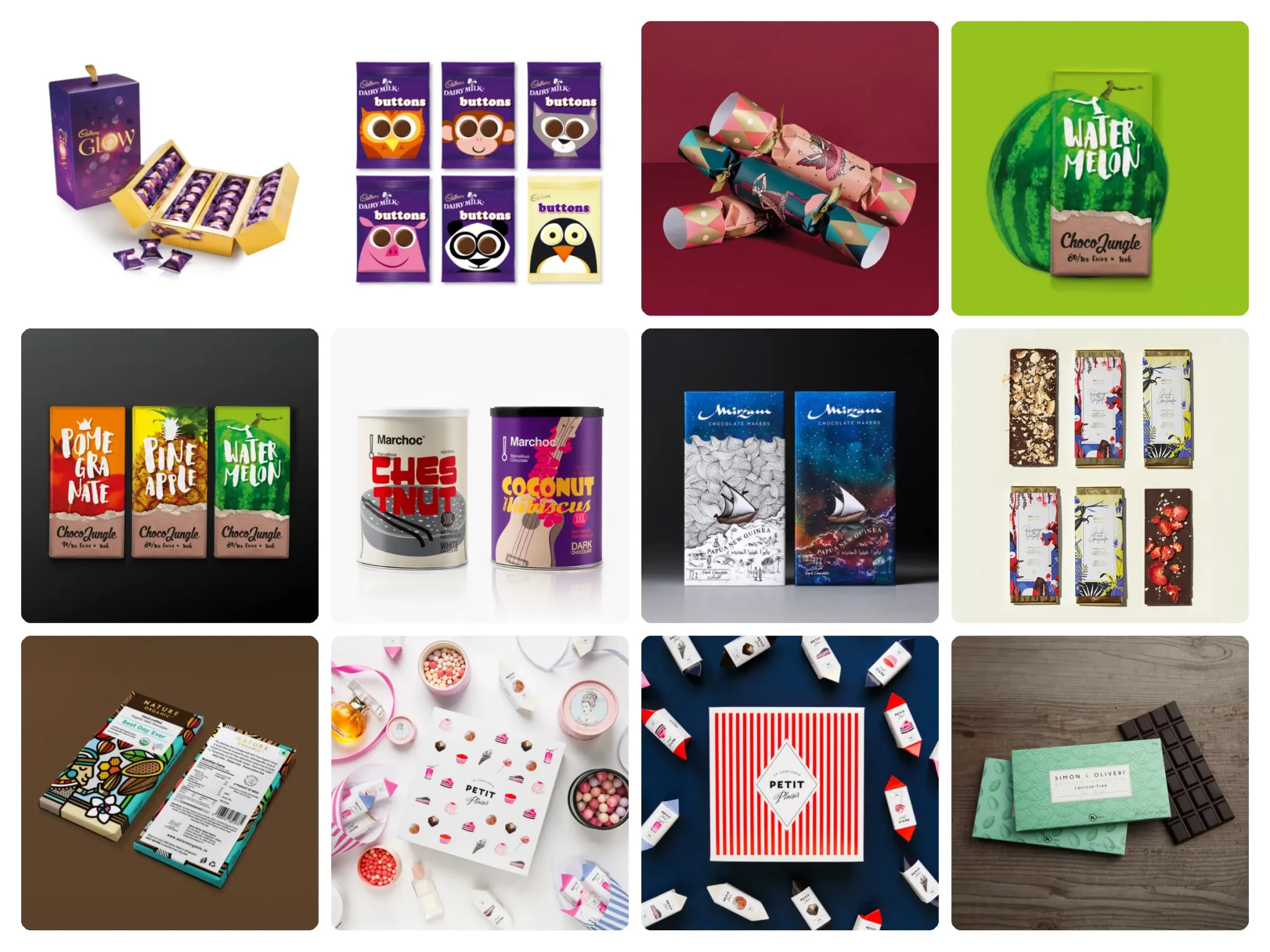

30 Honey Packaging Designs That Capture Nature’s Sweetness