What are the differences between primary packaging, secondary packaging, and tertiary packaging?

When we shop in the supermarket, we can see all kinds of products, which have all kinds of packaging. Although they vary in shape and design, most products are classified as either first-grade or second-grade packaging. However, if you visit the storage area of the same supermarket, you will see grade three packaging on the industrial shelves.

What exactly are the differences between primary packaging, secondary packaging and tertiary packaging? How important is this classification system? Understanding the answers to these questions is crucial for formulating marketing strategies and improving the packaging and transportation processes of different products.

What is first-level packaging?

If you purchase a can of soda from a vending machine, you can drink it without opening any additional packaging. In other words, the can in your hand is of Grade one packaging. Generally speaking, if it comes into direct contact with the product, it belongs to the first-level packaging. The main purpose of primary packaging is to protect and preserve the product, and in most cases, to facilitate the handling of the product. The primary packaging types are mainly divided into:

Soft packaging

Soft packaging uses materials such as aluminium foil, cellophane and paper. It is often used in foods such as potato chips and candies, as well as personal care products like shampoo and conditioner. Flexible packaging is easy to shape around the material.

Hard packaging

Hard packaging uses more complex materials, such as glass, metal and plastic, to maintain its shape. Hard packaging can be used for products that require protection against impact or temperature changes, such as electronic products, beverages and medicines.

Semi-hard packaging

Semi-rigid packaging is a hybrid of flexible and rigid packaging, using conformal materials such as foam and cardboard. Semi-rigid packaging materials are easy to bend or shape and are usually used for products that require certain anti-collision protection, such as eggs or wine bottles.

What is the important role of primary packaging?

From the perspective of consumers, primary packaging is the last line of defense that isolates them from the product.

However, from the manufacturer’s perspective, it is the first line of defense to protect the product from damage. Although primary packaging is particularly important for perishable goods and food, for non-perishable goods, primary packaging must also provide sufficient protection.

The first-level packaging can protect the product from damage such as impact, tearing and puncturing; Prevent overflow (especially for liquid goods); Or prevent exposure to environments that may cause it to deteriorate, such as the exposure of grains to sunlight. For these reasons, seeing torn or damaged packaging is enough to drive consumers away from your product and turn to your competitors.

Seeing defective first-level packaging often leads consumers to believe that the products inside have been damaged before being put on the shelves, thus causing misunderstandings about your company’s quality control.

What is secondary packaging?

Secondary packaging is a layer of protection around the main packaging of the product. Its design can protect a variety of products during transportation and storage, and can also be used for brand promotion and marketing.

Suppose you don’t want to buy a can of soda from a vending machine, but rather a case of 12 cans of soda from a supermarket. The paper box containing these 12 cans of soda is called a “box”, which is a type of secondary packaging. Secondary packaging refers to containers used for carrying and storing a specified number of main containers. Although secondary packaging may exist in various forms and the quantity of products it contains also varies, a specific secondary packaging usually contains multiple goods belonging to the same stock unit (SKU). Common examples of secondary packaging include corrugated cartons, gift boxes, plastic boxes, shrink wrap, etc.

Secondary packaging usually serves two purposes: to provide additional protection for the product and to facilitate storage.

The protective effect of secondary packaging varies greatly, ranging from completely non-existent to highly effective, depending on the nature of primary packaging and the manufacturer’s priorities in product display and brand promotion.

Secondary packaging must also be capable of easily storing a fixed number of specific SKUs (inventory units), which means they should be easy to stack and store. The stackability of secondary packaging is crucial for avoiding space waste during storage and transportation.

What is the third-level packaging?

If you see 12 bottles of soda on supermarket shelves, they are very likely not repackaged when they leave the factory. If you take a look in the storage room of a supermarket, you will find multi-layered packaging boxes placed on pallets, usually wrapped with shrink film to keep the boxes together. This kind of packaging is called tertiary packaging, also known as bulk packaging or transport packaging.

The purpose of tertiary packaging is to combine a large number of secondary packaging containers into a unit, known as a distribution unit, to facilitate loading and unloading between the warehouse and transport vehicles.

Pallets, also known as pallets in some countries/regions, are the global standard for Grade three packaging. The design of the pallet makes it easy to move through another major tool of the storage facility – forklifts.

Palletized goods are fixed and protected during transportation to prevent damage, providing at least three layers of protection for the products, making them more resistant to rough handling and volatile transportation conditions.

Whether it’s primary packaging that protects the product, secondary packaging that enhances brand image, or tertiary packaging that optimizes logistics efficiency—each layer plays a crucial role in your product’s journey. Looking for tailored professional packaging solutions for your products? As trusted luxury paper packaging suppliers, KALI offers free & fast design services and a 24/7 online service team with our own specialized packaging manufacturing facility.

From eco-friendly molded pulp packaging to luxury paper boxes, KALI offers end-to-end packaging design and production services, helping you balance functionality, sustainability, and brand aesthetics. Explore our customized solutions today and transform your packaging into a strategic advantage!

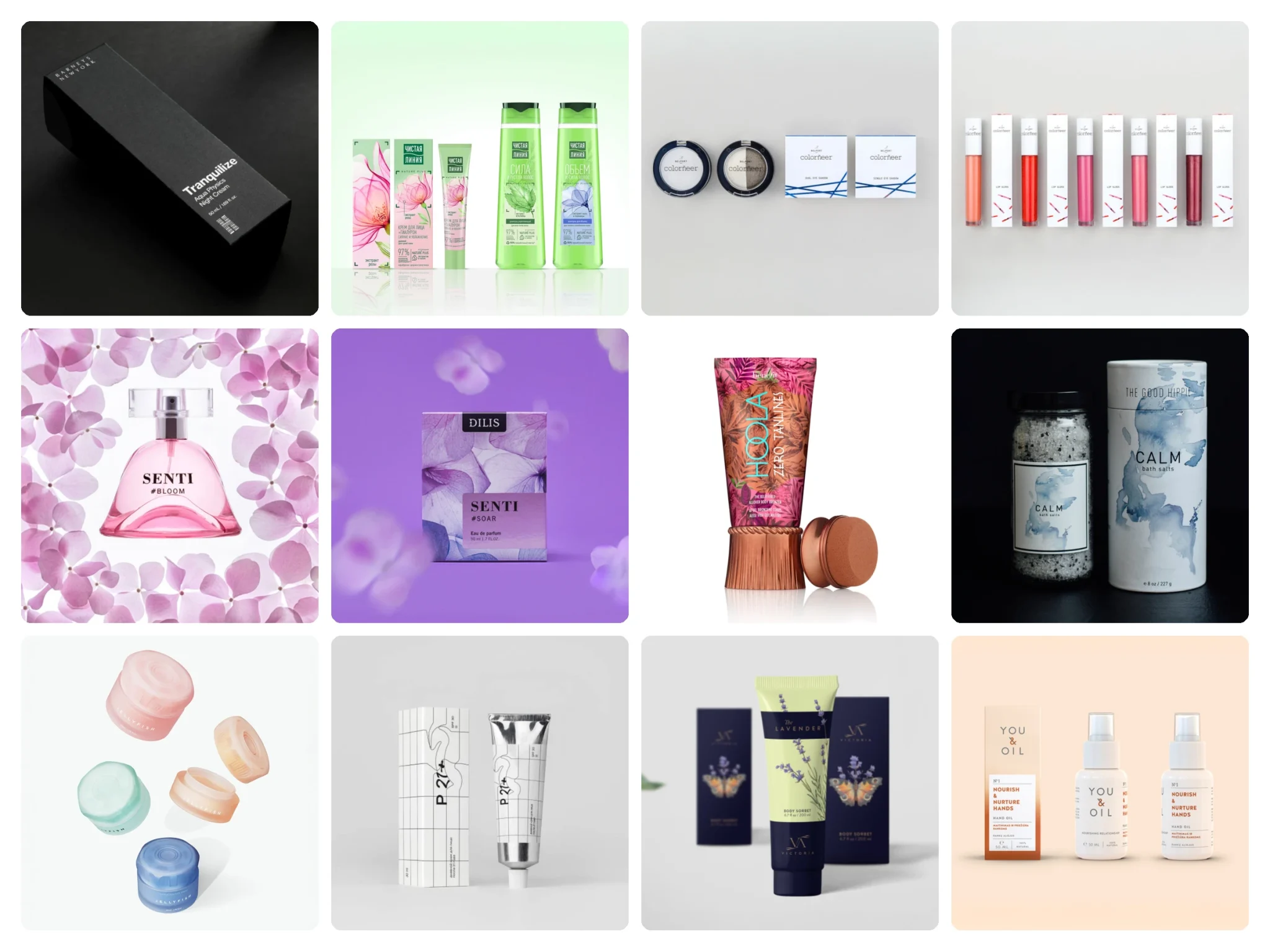

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

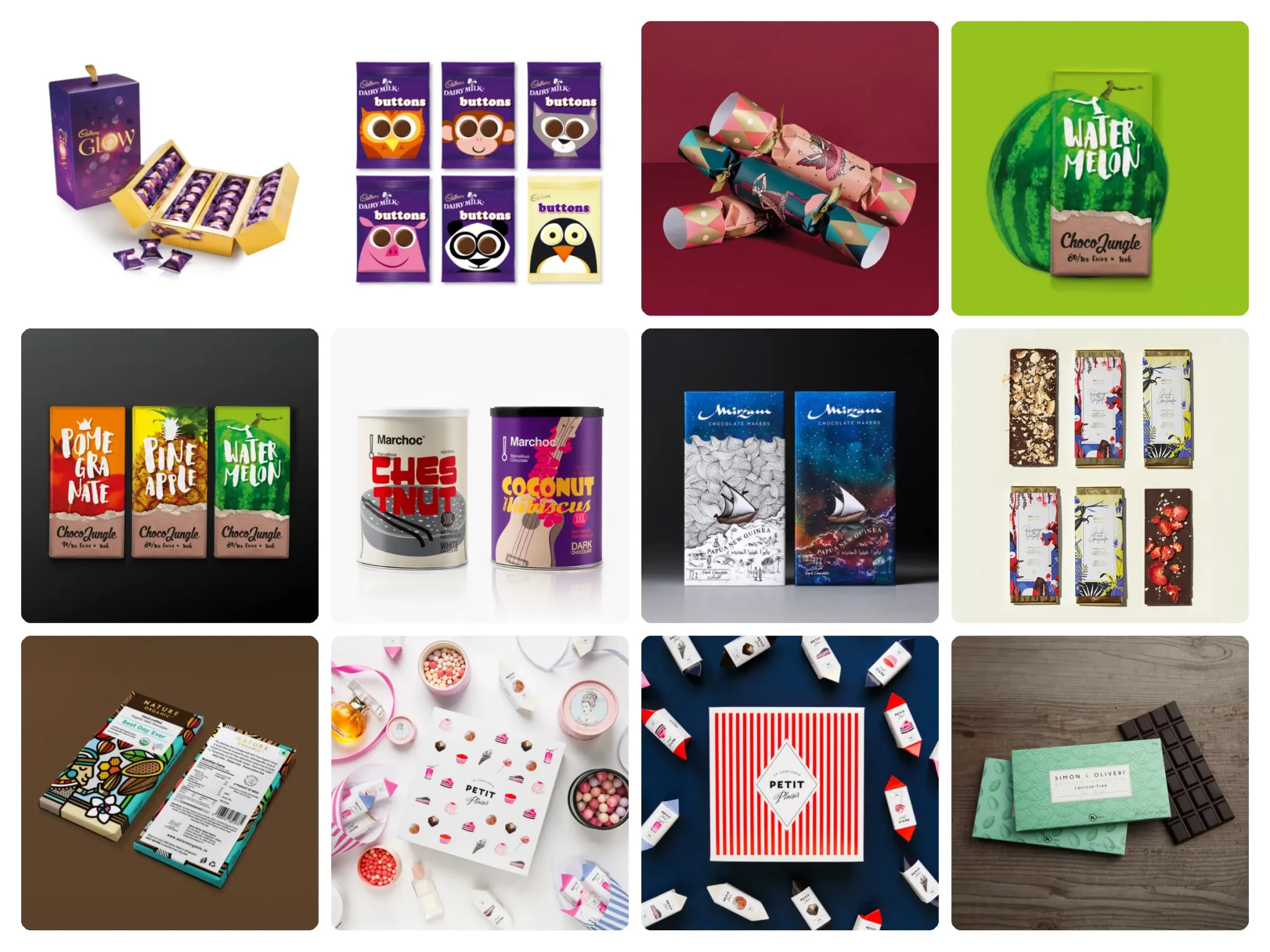

30 Honey Packaging Designs That Capture Nature’s Sweetness