New Environmentally Friendly Packaging Has Become The First Choice

Beautiful packing bags will eventually become a burden in our life. Because most of these packaging materials contain polymer compounds such as polystyrene, polypropylene, and polyvinyl chloride, they are difficult to break down. According to the report, 7 percent of home garbage is packed with waste plastic roughly, 190000 tons every year. The problem of “white pollution” of discarded plastics is growing more and more serious. The state has issued a plastic prohibition order, and it is time to fix it.

In reality, how to reduce “white pollution” has become a global concern. Western Europe, the United States, Japan, and other affluent countries have officially forbidden the use of disposable foam packing materials. However, many of the remedies that governments have implemented have certain flaws. For example, photolysis components need to be added to the regular foam, but photolysis is not simple to complete, leaving small fragments; And restricts the recycling of waste paper, but the recycling operation takes a long time, and it is difficult to assure the recovery rate. In addition, paper goods can match the needs in some regions, but the papermaking process will also produce large pollution. Obviously, it is a required trend for biodegradable plastic bags to replace standard plastic bags.

Now, the job of making entirely biodegradable resin materials and foamed plastics using carbon dioxide as the primary raw material is steadily focused, kicking off an increase of research on biodegradable packaging all over the world. In addition to being utilized as packaging materials, biodegradable plastics also have strong biological adaptability and biodegradability, therefore they are also quite prevalent in the medical area.

Biodegradable plastic bags mean that under natural conditions such as soil and/or sandy soil, and/or specific conditions such as composting, anaerobic digestion, or aqueous culture medium, they are degraded by the action of microorganisms such as bacteria, molds, and algae existing in nature, and finally completely degraded into carbon dioxide (CO2) or/and methane (CH4) Water (H2O) and mineralized inorganic salts of its elements as well as plastic bags of new biomass.

Polylactic acid (PLA) is a novel form of biodegradable material. Now, it is a more biodegradable plastic bag material, which is formed of starch raw materials supplied by renewable plant resources (such as maize) (such as corn). With strong biodegradability, it can be totally decomposed by microorganisms in nature after use, and eventually create carbon dioxide and water, which does not damage the environment, which is very advantageous to environmental protection and is considered an ecologically benign material.

The degradation of PLA may be separated into two stages: 1) initially, pure chemical hydrolysis to lactic acid monomer; 2) Lactic acid monomer is degraded into carbon dioxide and water by bacteria. The meal cup constructed of poly lactic acid may be totally decomposed in about 60 days, truly accomplishing the combined impacts of ecological and economical.

PHA, another frequently used biodegradable plastic bag material, is generally utilized to manufacture biomaterials in the area of surgery, such as surgical sheets, bandages, lubricating powder for surgical gloves, etc. It can also make membrane products compatible with blood. It may also be utilized as vascular grafts, vascular replacements, and crack fixing plates. In addition, innovative medicinal materials such as bone plates, bone nails, and three-dimensional scaffolds can also be employed in tissue engineering.

It is estimated that by 2010, the market demand for biodegradable plastics throughout the world would rise by 30 percent per year. By 2010, the market scale of biodegradable plastics would expand to 1.3 million tons, and the manufacturing capacity will reach 1 million tons. Not only the United States, Germany, Italy, Canada, Japan, and other nations, but China will also become a key country producing biodegradable plastics. Kali Packaging is devoted to the application and research and development of biodegradable environmental protection materials, and the creation of biodegradable packaging goods to fulfill the demands of diverse market areas.

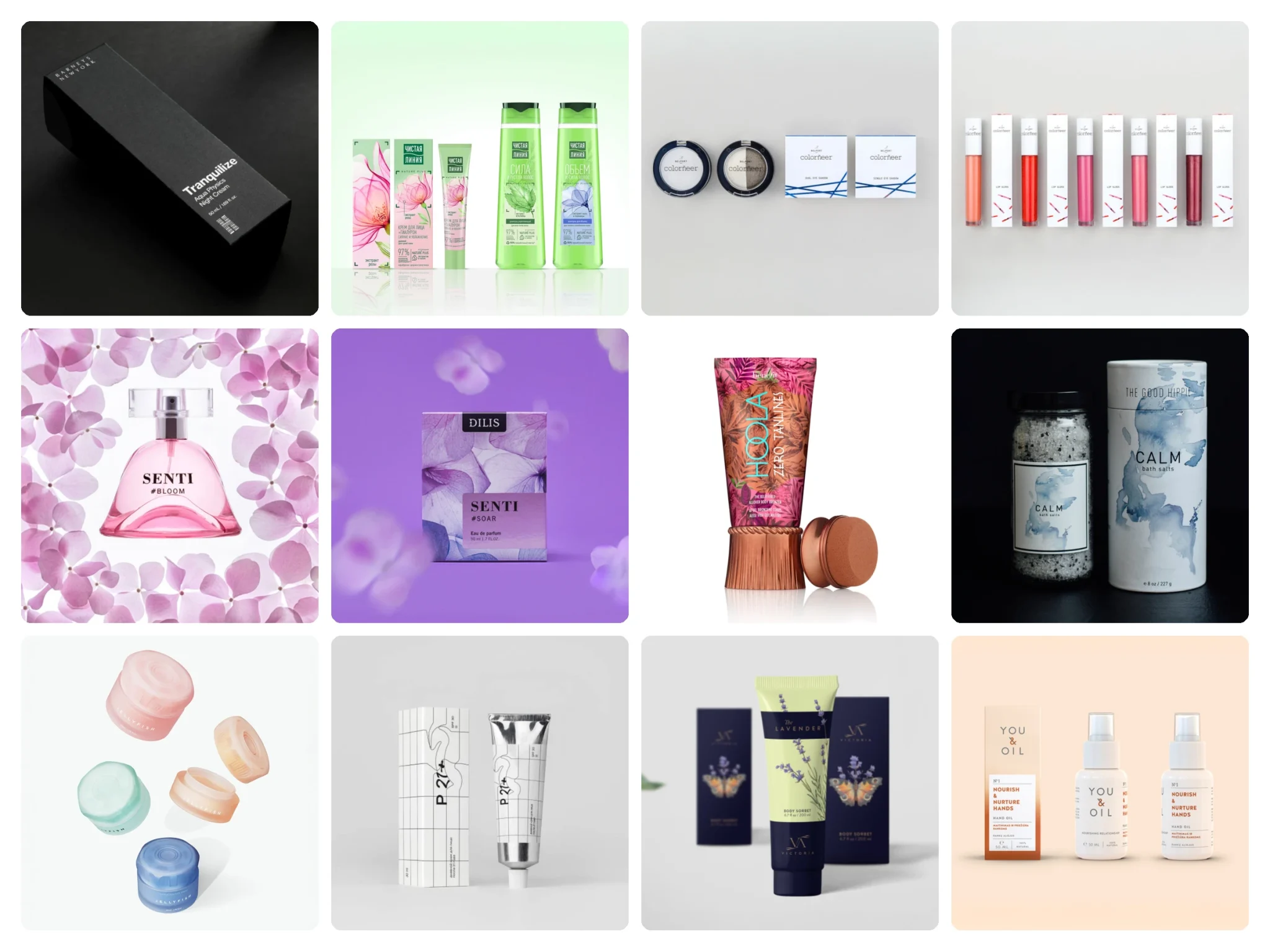

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

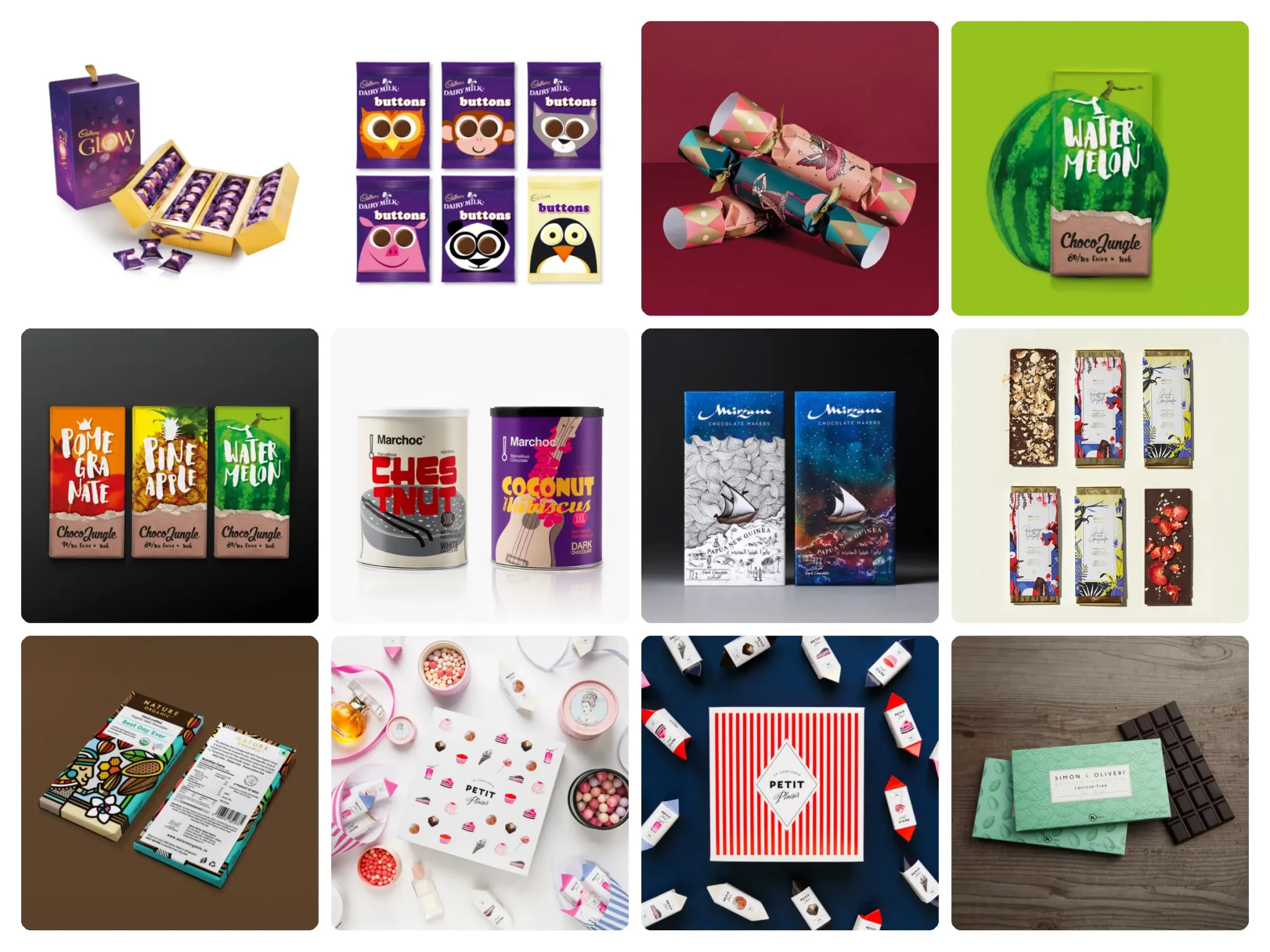

30 Honey Packaging Designs That Capture Nature’s Sweetness