How To Choose Best Box Packaging Types To Start Your Business 2021

Packaging plays an important role in the sales of products. Compared with the past few years, packaging materials have not changed much. Due to the variety of bags and boxes available in the market, it is often difficult to choose the most suitable box packaging for your product. Let’s look at some of the best packaging types in 2021 that can be used to promote your product and enhance the customer experience, in order to start your business successfully.

How To Choose Best Box Packaging Types To Start Your Business In 2020

- Carton Box Packaging

Cardboard is the material of paper, light and strong. You can easily cut and manipulate them to create custom shapes and structures. These features are most suitable for personalized packaging. It’s pulp made of wood or waste paper and then bleached. There are different grades of paper gift box packaging, each suitable for different packaging requirements.

SBS (or solid bleached sulfate) paperboard can be used for cosmetics packaging, medicine packaging, tea packaging, food packaging, etc. The choice of kraft paper and Cuk (coated unbleached kraft paper) cardboard packaging is chosen by people who like natural and environmentally friendly recycled paper (which can also be used for packaging purposes). Generally speaking, kraft paper has poor moisture resistance, so it is not suitable for food related products or frozen food packaging. Through the right combination of design, cardboard packaging can look very high-end, without high-end price.

- Corrugated Paper Box

Corrugated paper box simply refers to: cardboard. Corrugated boxes are considered cardboard by many people because they can produce large transport, shoes and storage boxes. Many people do not know that there are different types of cartons, depending on the durability and strength of the carton. However, it is easy to identify a corrugated material. How do you determine the material? Through its corrugated medium (also known as grooving). It’s easy to identify corrugated materials. It consists of three layers of paper, an outer liner, an inner liner and a corrugated medium (also known as a groove). A corrugated medium endowed with strength and stiffness.

The main raw material used to construct corrugated paper is a lot of recycled paper, which is made by large-scale high-precision machinery called corrugated paper. These types of boards can be reused and recycled over and over again as a source of pulp fiber. There are different types of corrugated board, single-sided, double-sided (single wall), double wall and three-layer. They can be used to make packages with different characteristics, performance and strength. The board is cut and folded into different sizes and shapes to form corrugated packaging. Other applications of paperboard packaging include retail packaging, external packaging, daily consumer goods packaging, etc.

- Plastic Box Packaging

Plastic box is widely used in daily product packaging. But it is gradually replaced by paper, leather, glass, ceramics, metal packaging and many other traditional materials.

Metal box packaging has many advantages of recyclability, usually they are more durable than cardboard box and plastic box. Sealed metal packaging can help maintain food quality and eliminate any contamination problems. The packaging is not easy to break and can be stored with food under extreme conditions. Another reason why metal is popular is that it can better protect products. It’s also flexible, lightweight and can be carved to enhance the appearance of the package. Compared with common materials, metal boxes have a higher recycling ratio and require less energy for production. Most of all, it’s very cost-effective!

- Cardboard Box Packaging

I believe you always want to know the type of boxes they use to package luxury goods such as electronics or watches. You will feel that it is a kind of cardboard, but because of its durability and high quality appearance is still uncertain. This paperboard material is called hard box.

This cardboard box is made of highly concentrated cardboard and is four times thicker than the cardboard used in standard folding carton construction. The simplest example of hard shell in the real world is the hard shell installed with electronic products. There are two types of fixed hard shell.

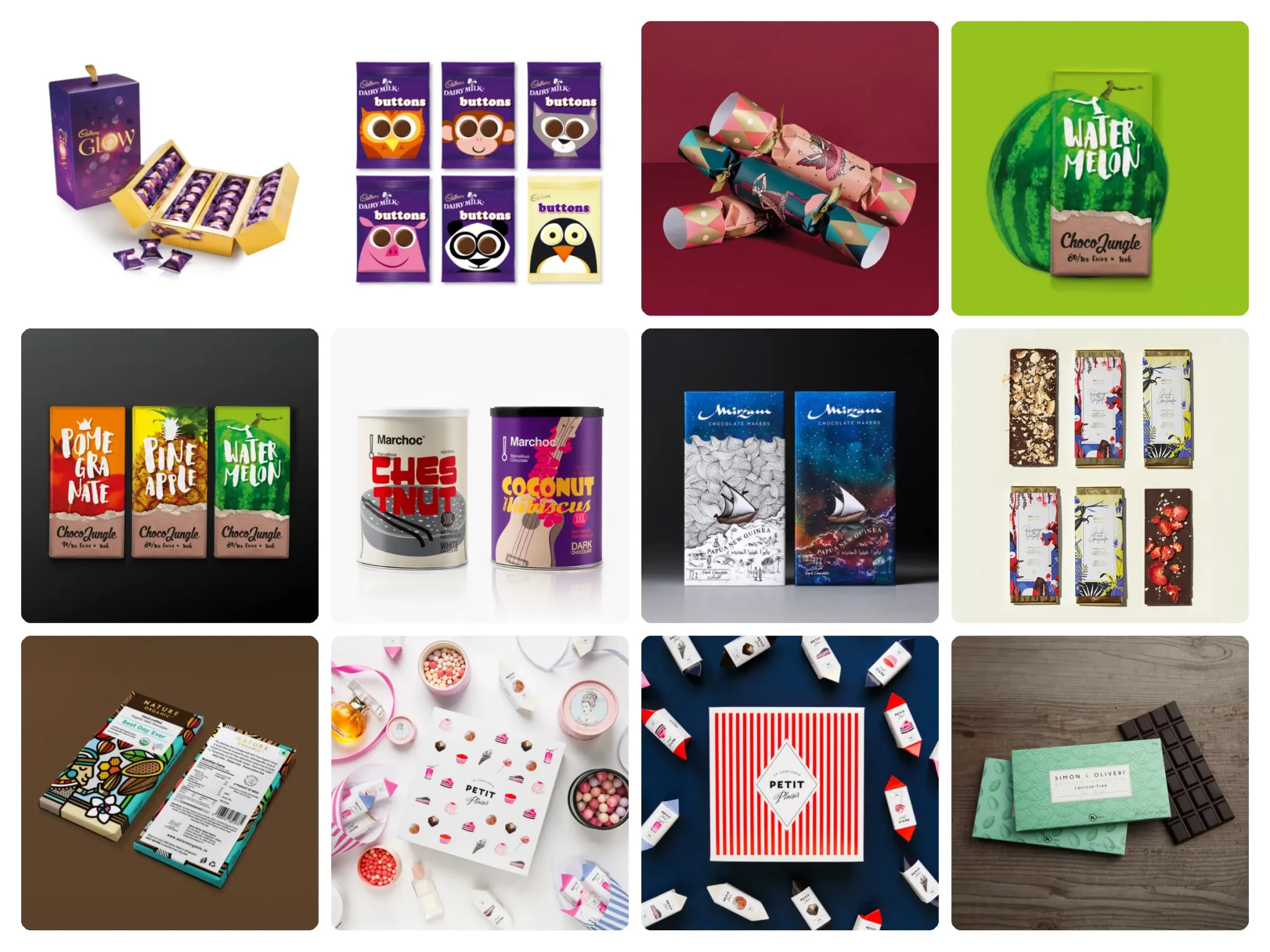

Compared with corrugated box, the rigid box is indeed one of the most expensive box types. Rigid chocolate boxes usually do not require expensive or large mechanical molds and are usually manufactured by hand. Their non folding also make them larger in the process of transportation, which easily leads to higher transportation costs. These boxes are usually used in the sales of commodities, cosmetics, jewelry, technology and high-end luxury women’s wear.

- Particleboard Packaging

Particleboard packaging is used in electronics, medical, food, cosmetics and beverage industries. Particleboard is basically a kind of paperboard made from recycled pulp. It can be easily cut, folded and shaped. This is a cost-effective packaging option for your products.

It has various densities and its strength depends on the density of the material. If you want to print the image directly on the particleboard, you can use sulfuric acid bleach and can (clay coated back) to make the material more durable.

If your business involves heavy goods, you can’t use particleboard packaging, because particleboard is a lightweight material, suitable for many groceries, such as grains, biscuits, tissue boxes, etc. In addition, if the storage environment is full of moisture, cardboard is easy to weaken, and lead to discoloration and expansion.

- Tin Can Packaging

Can packaging is usually seen in most coffee and tea packaging. Why? It keeps the product dense to maintain flavor, protects it from bacteria and helps to extend shelf life. In addition to food, cans are also used to pack daily necessities and food. To keep the product tight and firm to prevent the growth of fungi and other bacteria. Nuts, grains, smoked fish, cheese and bacon are also canned to prevent spoilage.

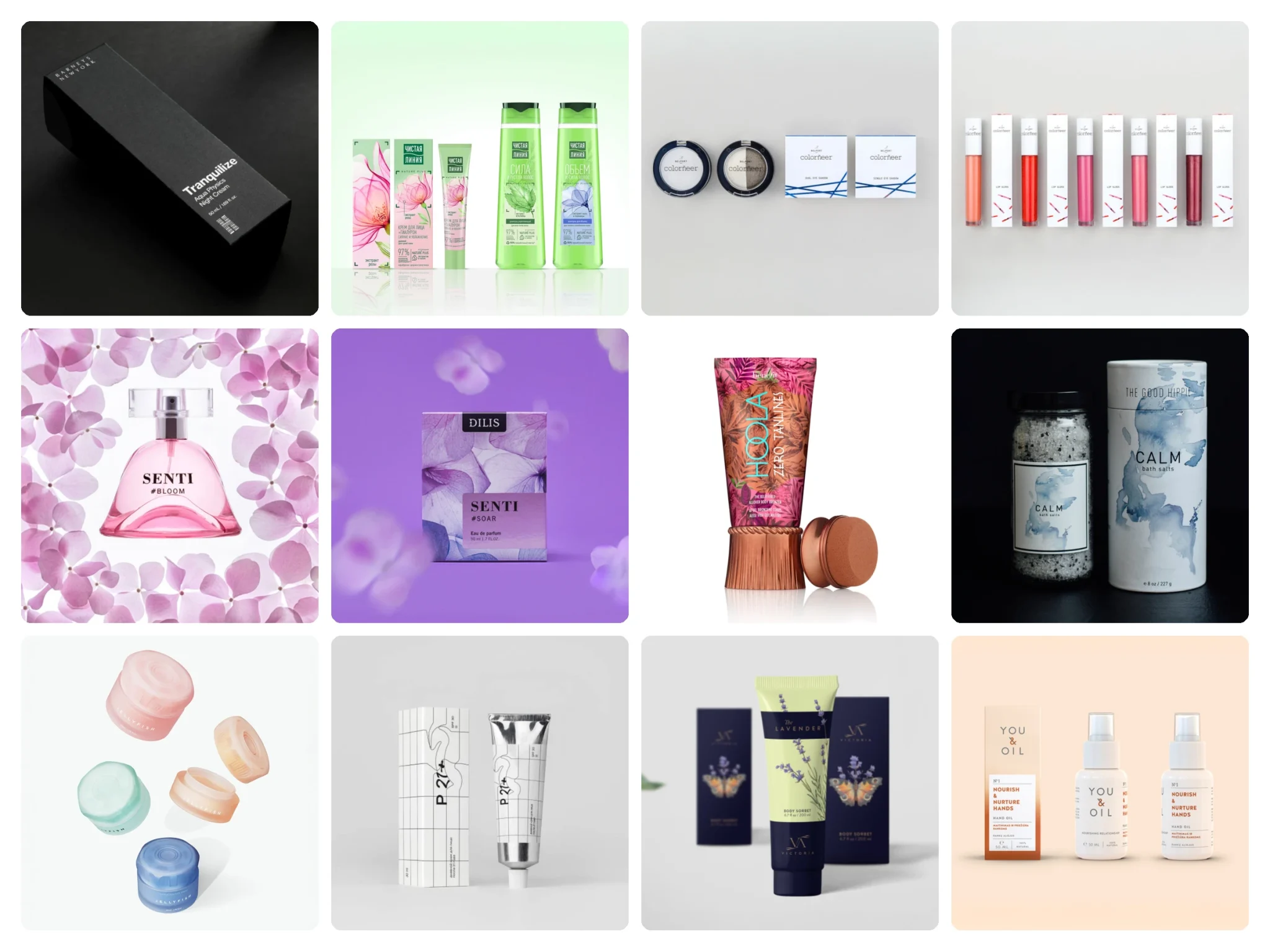

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

30 Honey Packaging Designs That Capture Nature’s Sweetness