How To Save Costs Of You Packaging – Budget Packaging Guide

Budgeting for packaging involves a wide range of considerations, many of which can be reduced by streamlining the present process. Setting a budget for a project like this is challenging, since no two companies are the same, and what works best for your packaging line may not work for anyone else in your industry. To maximize your potential for packaging cost reductions, you may need to go outside the box from time to time. Budgets are heavily influenced by your choice of collaborators and the timing of their arrival. Multilayer film, binding film, maintenance, and new technology are just a few of the other factors that might impact your total package cost.

A film with many layers

What exactly is a multilayer film?

The multilayer films are created by stacking various polymers, pressing them together via slotted dies, and then combining them before they cool. This allows each layer to have its own distinct advantages, as well as to be more easily processed and more durable. High-performance flexible packaging often makes use of multilayer films. These applications include (but are not limited to) shrink packaging, stretch packaging, pouch packaging, bagging, and flexible laminations.

Polyester, polyethylene terephthalate (PET), polyethylene terephthalate (PET),

Polyethylene (PE) is a heat-sealed food contact layer that is both moisture-proof and gas- and odor-resistant (EVOH, PA)

It is possible to apply a heat-sealing coating on polypropylene (PP), a gas/aromatic barrier that serves as a moisture barrier (acrylate, PVDC)

An outer layer of Polyamide (PA) offers processability, gas and odor barrier, heat resistance, and does not attach to the sealing strip.

PET – a gas and aromatic barrier, a moisture barrier, a heat-resistant material, and a material that provides machining strength

moisture must be prevented by a vinyl alcohol oxygen barrier, often between polyethylene and polypropylene (PE/PP).

Gas-permeable, printable polystyrene (PS) may be integrated with various gas and aromatic barriers, making it a versatile barrier material.

Plastics made from polycarbonate (PC) have excellent processing properties, are moisture-resistant, and are heat-resistant.

As a 2nd barrier layer, it provides gloss and protection, as well as printing and heat sealing. Polyvinylidene chloride)

An adhesive layer, moisture barrier, heat sealant, and food contact layer are all provided by vinyl acetate.

Ethylene acrylic acid aluminum foil (EAA) and other polymers are connected by (EAA)

Processability and heat resistance are all advantages of polyethylene filament mesh (used in pens).

A polyethylene terephthalate food contact layer that has been ethoxylated with ethylene glycol

Gas / scent barrier, ease of processing: Polyvinyl Chloride (PVC).

Food and other consumer goods packaging may make use of any one of these polymer layers. Depending on the application, each has benefits and disadvantages. When creating multi-layer packaging, be sure to pick wisely.

Why use multi-layer coextrusion film instead of single-layer coextrusion film?

Flexible packaging options: multi-layer film may be tailored to fit your product, brand, and packaging needs.

These layers can be combined with sustainable development by using non-oil, renewable resins, such as maize straw and sugarcane, and even recyclable materials. In order to recycle multilayer flexible packaging, such as aluminum foil-coated polyethylene laminates (commonly found in tiny bag packaging), the layers must be separated and then recycled. In other words, it isn’t an environmentally friendly way to package goods! Burning polyethylene may be used to create energy in a novel way.

Because manufacturers may optimize each layer independently, allows for more packages per roll and thinner films. Not only can you save money on packing, but the longer production runs and fewer rolling transitions make it easier to attain higher levels of productivity.

The duties of each layer in a five-layered extruded laminate packaging

PET, PA, and PE make up the first layer.

Sheet of paper to be printed out

Providing a buffer

Resilience to wear and impact.

Tie the second layer (AI, foil, EVA)

The barrier layer should be layered over the outer layer.

A barricade to keep out the bad guys

A third layer of protection (EVOH, PEN)

Optical transmission is protected from moisture (MVTR)

Oxygen shielding.

It’s time to tie the outer and inner layers together using this layer (EAA, PS).

A barricade to keep out the bad guys

Sealing glue layer, the last layer (PE, EVA)

Obstacles of their own

Protection in many layers

Put the product in its container and close the lid.

Heat sealing of the container is permitted.

How can I save money?

Maintenance: based on our experience, the multi-layer packaging extrusion technique often results in lower maintenance expenses than single-layer packaging. When using single-layer film on a packing line, it might be more viscous, resulting in longer cleaning times and more frequent machine repairs. It is possible to decrease the amount of residue on the sealing strip by using multi-layer film.

To minimize the number of items harmed by the film, it is possible to use multiple protective layers on the film. Repackaging. The multi-layered film provides increased strength and minimizes the amount of packing machinery maintenance required.

For bespoke multilayer, you’ll need to know what you’re searching for, which might be tough because there are hundreds of polymer resins and combinations available. Working with packaging experts can help alleviate some of the stress that comes with making the wrong film choice. If you have a good relationship with numerous film manufacturers, you will be able to benefit from their expertise and experience in the application and packaging of films.

Pre-packaged movies

The binding film can lower packing costs by more than 30 percent in some cases if your product can manage your supply chain. This is not unusual. Today’s films can hold larger items while keeping the same shape as a corrugated tray, making them ideal for supporting multipack products. High-resolution images may be printed on the film, therefore saving money on extra labels. Reduce your impact on the environment by reducing the amount of packaging you use. Only the bag contains the film.

Harm to the goods in transit

Product damage is reduced by 2.5 percent on average by these firms each year. You may quadruple the number of containers that can be filled and utilize the same quantity of film at the same time if you use the right packaging materials and current technology. Stretch film costs can be reduced by more than 30 percent when changing the packaging solution at the end of the manufacturing line.

Consumption of energy

For instance, you will notice significant gains in energy use if you replace outdated devices with modern technologies. Compressed air is one of the most expensive utilities in your facility if you break down your utility bill. Compressed air production costs can be reduced by converting to electric and pneumatic technology, which eliminates the need for cylinders that require long-term maintenance.

Wear in pneumatic machinery: In the past, pneumatic machinery has started wearing down with time, resulting in uneven sealing or cutting. Adding extra materials is a common solution used by machine operators to extend the life of damaged or worn-out pneumatic components. This is to keep the machine from breaking down. In order to rapidly assess your overall packing costs, simply add a half-inch or so of film to each product. There are several reasons why you may want to seek the advice of a specialist if you are utilizing pneumatic mechanical equipment and see an increase in film use.

Planned Time Off

As long as your packing machine receives routine preventative maintenance on a regular basis, downtime is more likely to occur when it is convenient for you, rather than when anything goes wrong. If you don’t have a regular afternoon meal in the United States, you’ll need to rely on specialists or create arrangements inside the organization. Prevent costly emergency repairs by keeping an eye on your maintenance expenditures, and you’ll save money when it comes time to send out an order at the end of the month.

It’s to your best advantage to consult box packaging pros before making any plans or budgets because they can help you save money and get the most out of your packaging operations. They can not only anticipate your demands, but they can also recommend the best products and equipment to meet them. You’ll also be able to take advantage of any discounts that the suppliers’ distributors may be able to provide by visiting various vendors.

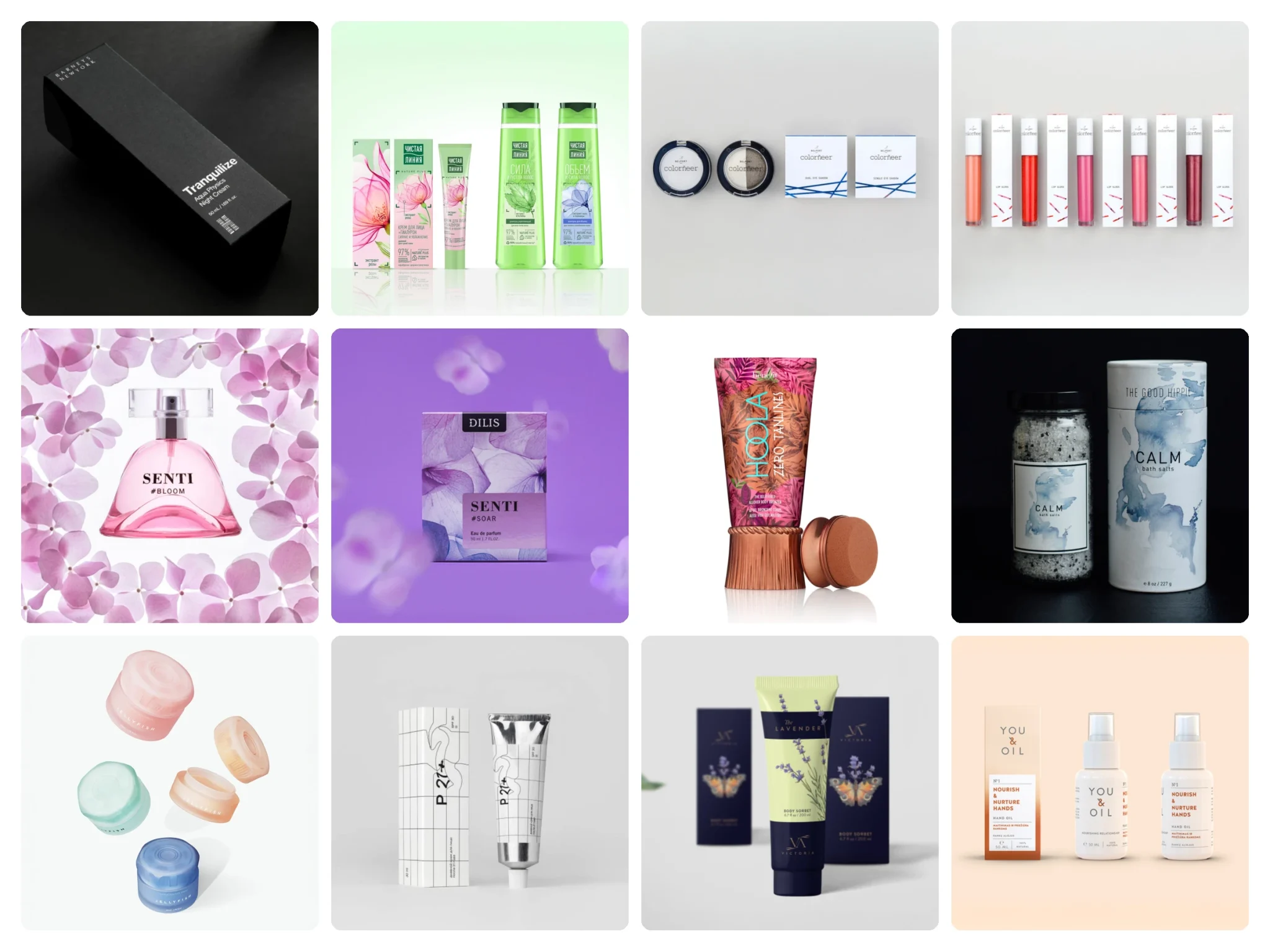

Top 10 Creative Cosmetic Packaging Design Ideas & illustrations 2023 | Luxury-Paper-Box.Com

30 Honey Packaging Designs That Capture Nature’s Sweetness